Extrusion is a process where the material is pushed through a unique tool called a die and then creates the objects of a fixed cross-sectional profile. There are three main advantages of this manufacturing

The next plastic extrusion die design type is called “Blown Film Extrusion.”

The blown film extrusion produces products such as shopping bags and continuous sheeting. Various types of plastic extrusion dies can be used in blown film extrusion, depending on the final requirements of film quality and characteristics of the polymer melt, such as spider, crosshead, and spiral dies.

– The Spider die, a complex die design, consists of an internal mandrel connected to the outer die wall by several “legs.” Based on the extrusion die design, it will have weld lines in the resulting film. However, weld lines are weaker than the surrounding polymer and have different optical characteristics caused by incomplete healing of the polymer molecular matrix. Besides, spider legs will produce a pressure gradient which will cause nonuniform die swell. As a result, the nonuniform film will become thicker.

– The Crosshead die divides the melt flow into two parts at the manifold inlet and recombines them opposite a cylindrical center mandrel. Compared to Spider die, this is a relatively simple extrusion die design that can result in non-symmetrical flow. Non-symmetrical flow happens because molecules will take longer to reach the opposite side than the close side of the mandrel. Thus, the resulting film cannot be of uniform thickness. Inlet diameters should be varied to reduce this nonuniformity, and different inserts need to be added to minimize stagnant regions.

– The Spiral die is the most complicated design among these three plastic extrusions die designs. It will evenly distribute the polymer melt into several feed tubes, which wind around a central mandrel. Each feed tube is connected to the space between the outer die walls and the mandrel. Thus, when feed tubes spin around the mandrel, their diameters will slowly decrease. Also, the space between the mandrel and outer die walls will be increased simultaneously. All these processes will allow the polymer melt to layer and blend, resulting in a uniform melt profile free of weld lines.

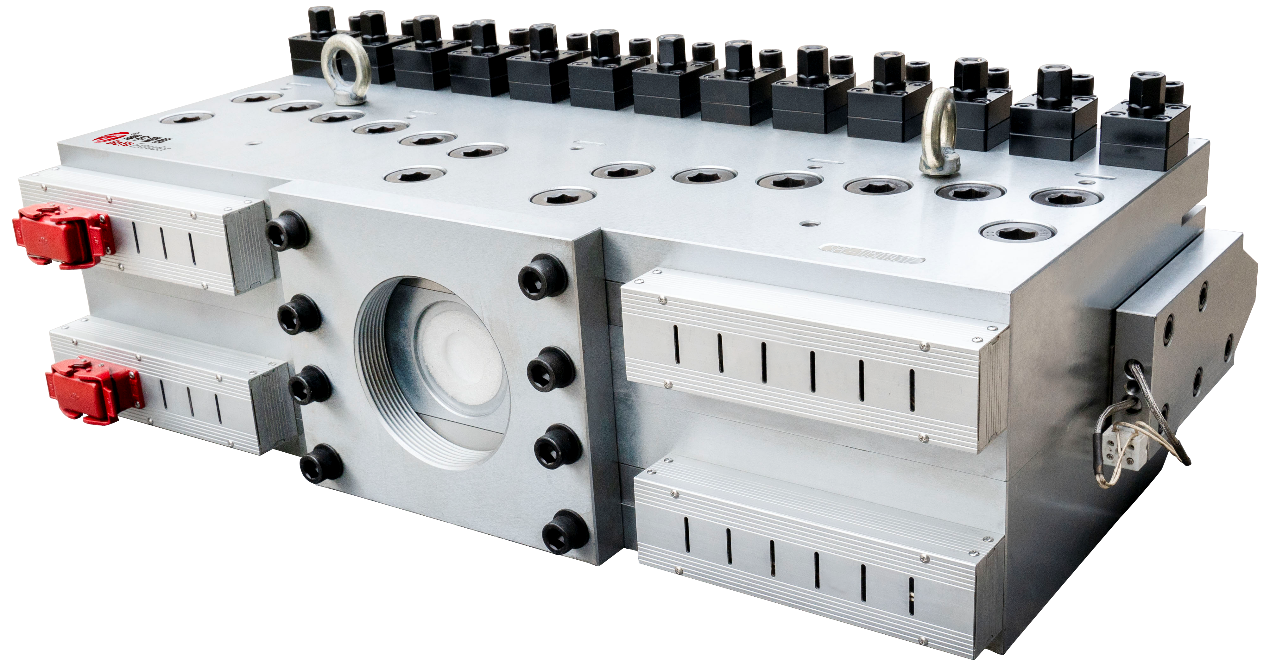

Pipe/Tubing Forming die

The last plastic extrusion die design type is “Pipe/Tubing Forming die.” Tubing forming die allows thick-walled tubes and pipes for continuous extrusion. This plastic extrusion die design shares remarkable similarities to the die in blown film extrusion. The significant difference is the gap between the inner mandrel and the outer die wall. The polymer melt’s cooling process will be finished using water baths or many cool fans. After cooling, the flexible tube will wound onto large spools, and the stiff tube will cut into preset lengths and stacked.

Why Choose Boyu

Boyu?Plastic Machinery Co., Ltd. is specializing in the production of PVC floor extrusion production lines.

We focus on technological innovation and research from product quality, environmental protection, and safety. We aim to make the equipment easy to operate, environmentally friendly, and safe.

Boyu has rich theoretical knowledge and practical experience studying plastic extrusion die designs. If you are interested in further information about plastic extrusion die designs, don¡¯t hesitate to check out our plastic extrusion die solution and

contact us for further questions.