Plastic extrusion is a manufacturing process commonly used for large-scale production. It involves heating and melting a polymer-based material with various additives. Then the molten material is given the desired shape by pushing it through a specialized matrix. The variety of plastic extrusion materials is almost limitless, and their use is growing rapidly with the development of advanced plastics.

Choosing the best plastic material for custom extrusion can be a daunting task. This article is a guide to plastic extrusion materials, which gives a general idea of the plastic extrusion process and discusses the types of plastic extrusion materials.

Plastic extrusion process

The extruder hopper is filled with solid raw materials at the first stage of the plastic extrusion process. This material is fed through the loading neck of the machine into the extruder drum. It is heated and moved by rotating screws. The heat and pressure inside the cylinder melt the thermoplastic resin before passing it through a separation plate equipped with grids that filter out pollutants and provide constant pressure.

The material then passes through the feed pipe into a custom die with the desired extrusion profile. The molten, pressed plastic retains the shape of the matrix, creating homogeneous components. After the material is extruded, the cooling system solidifies the parts evenly. Finished extruded profiles can be cut, molded, or otherwise prepared for further stages of the manufacturing process. Plastic extrusion is highly versatile and allows you to produce parts quickly with a uniform profile.

Types of Plastic Extrusion Materials

Plastic materials used in extrusion processes are classified by commercial availability as well as by molecular structure.

1. Commercial Classification

For commercial purposes, plastic extrusion materials are grouped by cost, market share, and material properties into a commodity, engineering grade, and high-performance.

Commodity Plastics (polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC) are suitable for most applications in the total use of thermoplastics. They are easily accessible, and easy to process.

Engineering Grade Plastics (polycarbonate (PC), thermoplastic elastomers (TPE¡¯s), polyamide (PA or Nylon), and acrylonitrile butadiene styrene (ABS) are designed with some combinations of properties to improve performance in specific applications.

High Performance Plastics are some of the most expensive plastics, so they are usually designed for special small-volume applications. High-performance plastics are designed to have exceptional mechanical and thermal properties to meet high-performance requirements in harsh environments.

Raw plastics can be mixed or improved according to most plastic extrusion applications.

2. Molecular Classification

Almost all plastic polymers have a mixture of two molecular structures, amorphous and crystalline.

Amorphous.The molecular chains in these polymers are quite entangled and move freely when the polymer is pushed or pulled. It gives excellent polymer elasticity and flexibility, elasticity, and can withstand tighter tolerances.

¡¤ Crystalline.The molecular chains in these polymers are very ordered and fixed in place. It cannot be easy to meet tight tolerances. As a rule, they have low impact resistance and demonstrate a high degree of shrinkage.

Thermoplastic extrusion in its current form has been around for almost a century, but it remains a powerful tool for the large-scale production of continuous profile parts.

Boyu Solutions

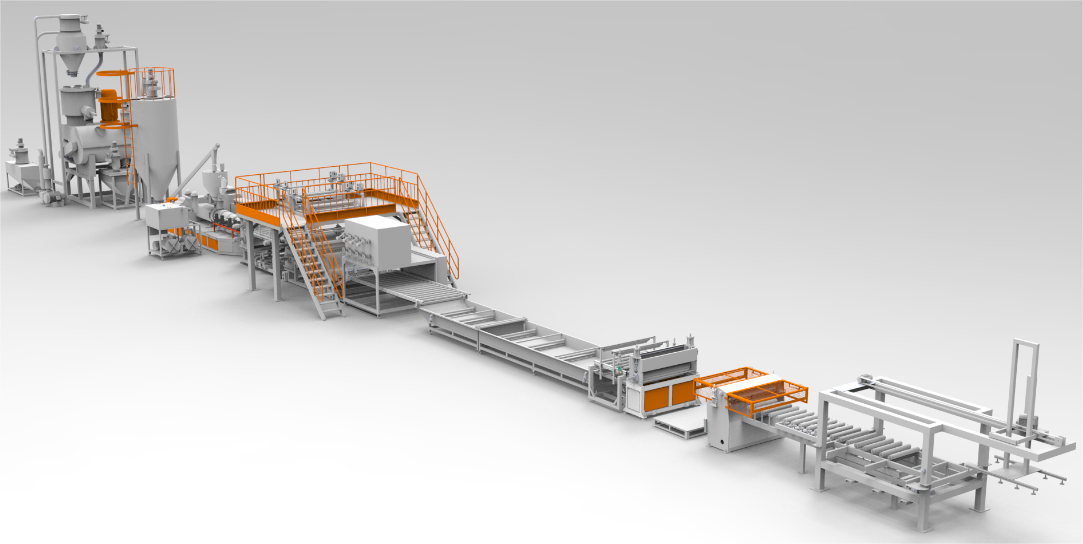

Established in 1998, Wuxi Boyu Plastic Machinery Co Ltd specializes in producing PVC Flooring Extrusion Production lines. The company has more than 90 technical patents and more than 20 years of rich extrusion experience and advanced extrusion technology! We provide high-quality plastic extruder equipment and production lines. Our company integrates design, production sales, and after-sales service. Boyu has different product categories of flooring production lines, such as SPC, LVT, PP, and other production lines.

Boyu¡¯s business network spans the globe. Contact us for a quote!