Extruders play an integral role in the flooring manufacturing process. These machines help evenly mix various raw materials including PVC powder, calcium carbonate, stabilizers, etc. They then shape the blended compounds continuously into floor planks and tiles on a large scale.

Selecting the appropriate extruder type is essential for floor producers. A quality twin screw extruder helps achieve high material throughput rates, it also ensures consistent quality and optimal lifecycle costs. In short, the right extruder choice can make or break production efficiency and profitability.

Comparing Single and Twin Screw Extruders

Single and twin models represent the two most common extruder types used for flooring production. Understanding how each works provides insight into their different capabilities.

Single Screw Extruder

This type contains a single rotating screw inside a stationary barrel. It works by continually feeding and conveying materials down its barrel. There, they are mixed and shaped using just the mechanical shearing and working of the single screw rotation.

Twin Screw Extruder

A twin screw extruder features two co-rotating or contra-rotating intermeshing screws inside a barrel. It simultaneously conveys and intensely mixes materials through mechanical shearing. At the same time, it also uses friction heat generated between the interlinked screws continuously working the material.

Key Differences

While single and twin screw extruder models perform the same compounding functions, there are notable variations in their designs, operations, and efficiencies:

lDesign: A single screw extruder only has a basic cylindrical barrel design and features a single rotary screw. While a twin screw extruder contains two parallel counter-rotating screws which are placed within a more complex dual-shaft system.

lOperation: A single screw typically rotates at slower speeds in the 50-300 RPM range for material processing. Twin screws, on the other hand, can operate at higher speeds from 200-1,000 RPM. The twin screw extruder can easily blend ingredients through friction as the two intermeshed screws counter-rotate.

lEfficiency: Because of its simplified single screw design, a single extruder often has productivity limitations. These are evident in both material output per hour and consistency of mixtures for large-scale production needs. However, twin screw extruder models address these concerns through more vigorous mixing of components at a time. They also boast enhanced conveying abilities to ensure higher outputs of well-dispersed compounds.

Why Twin Screw Extruders Are Superior for Flooring Production

Flooring production requires consistent mixing of various raw materials to achieve uniform quality in final outputs. It also needs high throughput to mass manufacture planks and tiles on a large scale. Compared with single screw extruders, twin screw extruder models are especially suited for these needs due to their key advantages. These include:

¨¹Higher Output: With counter-rotating intermeshing screws, twin screw extruder types can process higher material volumes per hour.

¨¹Better Mixing: Their parallel rotating shafts intensively blend ingredients, ensuring consistent mixtures for reproducible quality.

¨¹Consistent Quality: As a result of thorough mixing, twin extruders maintain stable properties across every floor plank and tile produced.

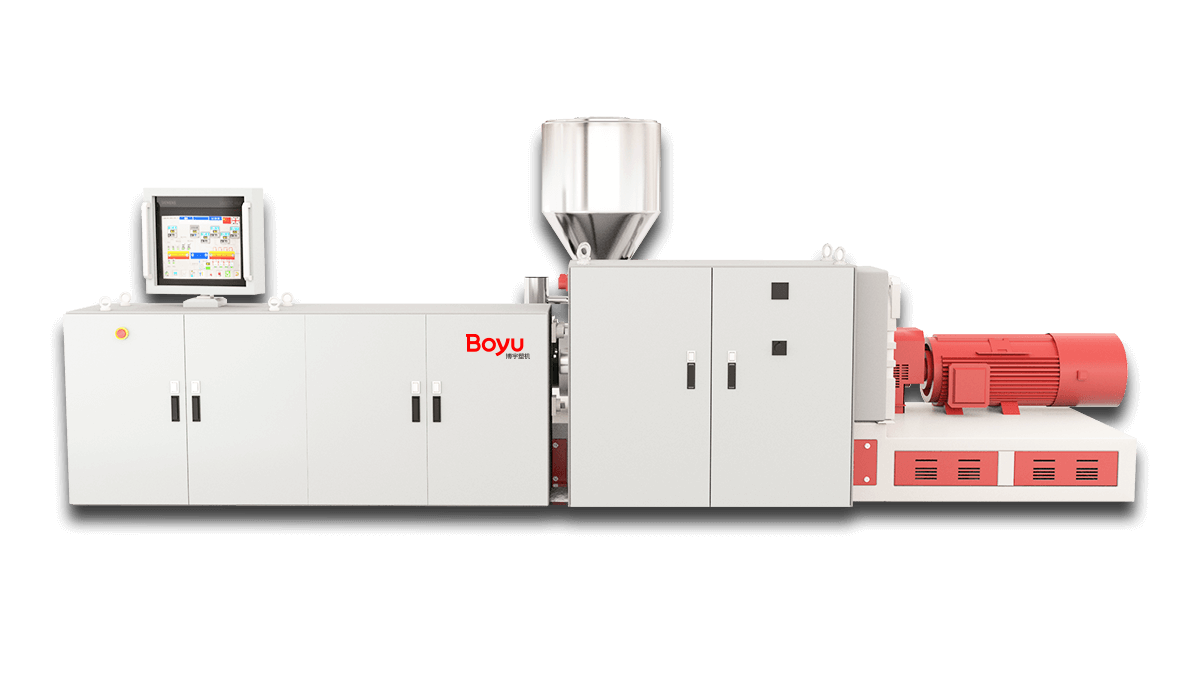

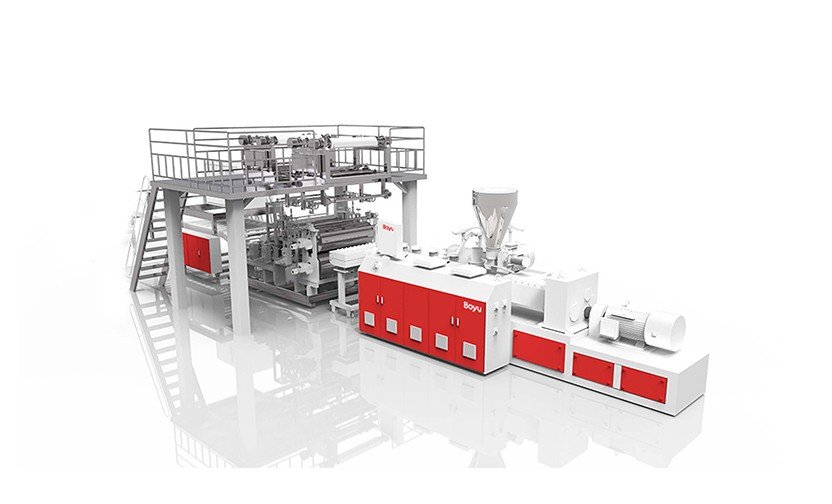

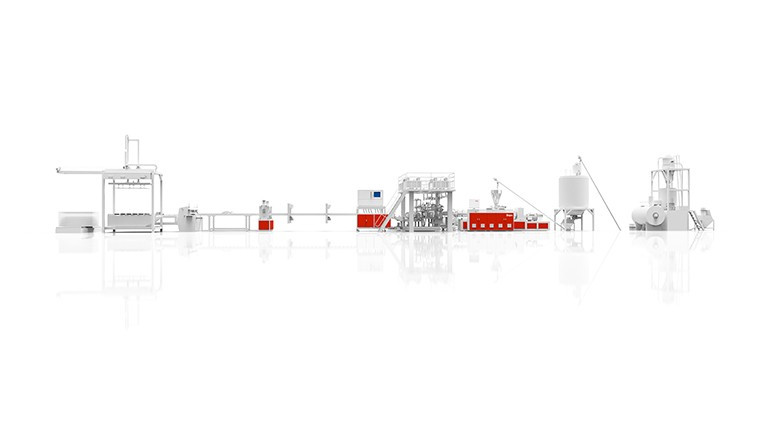

Boyu¡¯s Twin Screw Extruders for Flooring

Established in 1998, Boyu is a leading manufacturer of PVC flooring equipment, including advanced twin screw extruder models. As a premier extrusion machine manufacturer, we offer three twin-screw production line options: Our SPC Conical Screw Line uses conical twin screws for high output. Our SPC Parallel Screw Line employs parallel screws for mixing enhancement. Our innovative SPC Building Block Line is customized for modular flooring. Key benefits of all these twin screw extruder models include:

¨¹User-friendly PLC+HMI control allows for simple operation

¨¹Premium gearboxes and bearings ensure reliable performance

¨¹Intensive mixing screws produce floors with uniform consistency

¨¹Modular designs enable customized configurations for different needs

¨¹Compliance with international quality standards for peace of mind

It should be noted that our conical twin screw extruder model SZJZ-180 has a strong daily capacity from 80-100t, at the same time with fewer energy cost.

Conclusion

To sum up, twin screw extruders are superior to single screw models for the high output and consistent quality demands of floor manufacturing. Their ability to intensely blend raw materials is unmatched.

As top suppliers, we at Boyu strive to deliver the most innovative extruder systems as well as top-notch floors. We back our expertise with a customer-centric approach focused on accelerating your success. Visit our website or contact us to explore all twin screw extruder types and do not hesitate to contact us for any inquiries!