What is Wet Extrusion

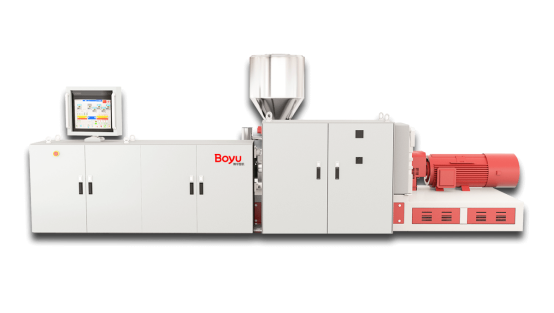

Boyu Extruder Wet extrusion is a manufacturing process that involves the production of complex profiles using a wet extruder machine. The process involves feeding a mixture of a material and a liquid such as water or oil into an extruder, which mixes and heats the material to form a homogenous mixture. The mixture is then pushed through a die to form a continuous profile, which is then cooled and cut into the desired size and shape.

Wet extrusion technology is widely used in various industries such as automotive and construction for applications such as weather stripping, seals, and gaskets. Boyu wet extrusion technology machines are designed to produce high-quality profiles that meet the specific needs of each industry.

The Advantages of Boyu Wet Extrusion

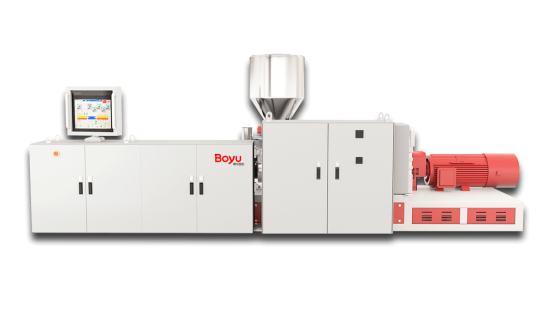

Wet extrusion technology is a highly efficient and versatile method for producing complex profiles made from a wide range of materials. The process involves feeding a mixture of a material and a liquid such as water or oil into an extruder, which mixes and heats the material to form a homogenous mixture. The mixture is then pushed through a die to form a continuous profile, which is then cooled and cut into the desired size and shape.

Increased design flexibility: Wet extrusion technology allows for the production of complex profiles with intricate designs. This means that businesses can produce profiles that meet the specific needs of industry and applications. Additionally, wet extrusion technology offers customization options that allow businesses to produce profiles that meet our specific needs, which can help to further reduce costs.

Increased production capacity: Boyu wet extrusion technology can help businesses increase their production capacity by producing profiles at a faster rate and with greater efficiency. This can help businesses meet our production goals and increase their revenue.

Durability: Profiles produced by Boyu wet extrusion technology are durable and long-lasting. We are resistant to wear, tear, and corrosion, making them ideal for use in a variety of environments.

Versatility: Wet extrusion technology is a versatile process that can be used to produce profiles from a variety of materials, including rubber, plastics, and metals. This means that businesses can use Boyu wet extrusion technology to produce profiles for a variety of industries and applications.

Improved surface finish: Wet extrusion technology produces profiles with a smooth and consistent surface finish, which is important for applications that require a tight seal or a specific aesthetic.

Conclusion

In conclusion, Boyu wet extrusion technology is a reliable and efficient option for businesses that require the production of high-quality profiles. With our cost-effectiveness, increased design flexibility, reduced material waste, increased production capacity, and durability, Boyu wet extrusion technology is a valuable asset to any business. If you¡¯re in the market for wet extrusion technology, then Boyu should definitely be on your list of options to consider.