Welcome to the world of plastic extrusion technology, where creativity meets functionality! Whether you're a curious enthusiast or an industry professional looking to expand your knowledge, this comprehensive guide is here to unravel the secrets behind this fascinating process. Join us as we dive into the intricate workings of plastic extruder machine, exploring its applications and uncovering how Boyu Extruder has revolutionized the game. Get ready to be captivated by a journey through innovation and discover why plastic extrusion is more than just molding¡ªit's shaping our modern world in ways you never imagined!

Introduction to Plastic Extrusion Technology

Extrusion is a process used to create objects of a uniform cross-sectional profile. A material is pushed through a die of the desired shape. The die shapes the material into the desired profile.

Extrusion is used in manufacturing processes where materials need to be formed into specific shapes. It is an efficient and cost-effective way to produce long lengths of material with a constant cross section.

There are many different types of extrusion, but all involve pushing material through a die to create the desired shape. Common applications for extrusion include creating pipes, tubing, and other hollow objects; as well as solid objects with a variety of profiles such as rods, bars, and beams.

Benefits of Choosing Boyu Extruder

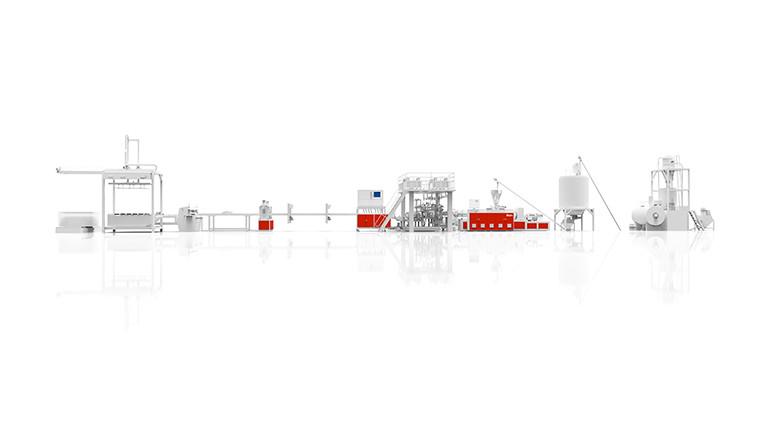

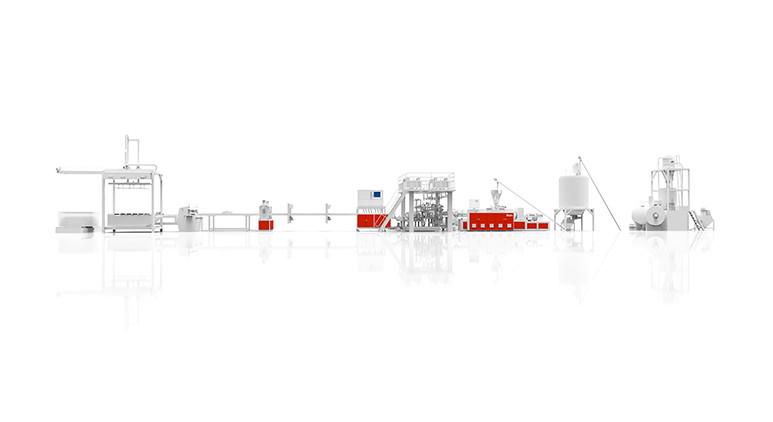

Since 1998, Boyu Extruder has been providing high-quality PVC floor extrusion production lines for enterprises all over the world. As the leader of SPC floor equipment, we have been selected as a supplier of high-quality plastic extruders by hundreds of customers from all continents.

Over the years, we have accumulated more than 90 technical patents, which is the result of our R&D team's efforts to innovate product lines and technologies.

As your reliable partner in the plastic flooring industry, we have rich experience in plastic extrusion technology and can provide you with high-quality, innovative and efficient extrusion production lines. Our product range includes complete system solutions from plastic extrusion manufacturing to the whole extrusion production line.

Our extrusion equipment is environmentally friendly, and the floor materials produced by our equipment do not contain formaldehyde and heavy materials. With reliable plastic extrusion manufacturing and the whole production line, we are the right choice to improve the efficiency and quality of extruded materials.

Conclusion

Plastic extrusion technology is a great way to create high-quality parts and components with excellent repeatability. With the help of this comprehensive guide from Boyu Extruder, you now have a better understanding of how plastic extrusion works and can make an informed decision about whether or not it is right for your product. Whether you¡¯re looking for strong, lightweight products made from long-lasting materials or need to save time on production costs, plastic extrusion could be the perfect solution. Invest in quality machinery and start exploring the possibilities that are available through plastic extrusion today!