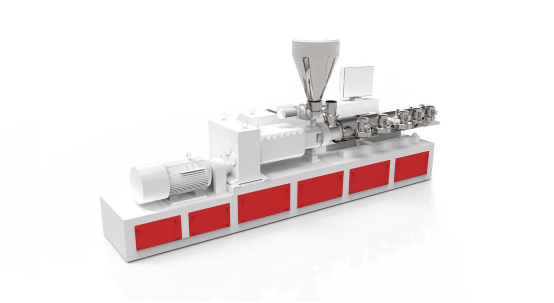

In the quest for manufacturing excellence, Boyu Extruder emerges as a trailblazing brand in the plastic extrusion industry. With a steadfast commitment to innovation, Boyu Extruder has developed a cutting-edge plastic extrusion line that empowers manufacturers to reach new heights of productivity and quality. As plastic extrusion plays a pivotal role across various industries, the demand for advanced solutions is paramount. Boyu Extruder's state-of-the-art plastic extrusion line offers unparalleled advantages, revolutionizing manufacturing processes and propelling businesses towards excellence.

Advanced Technology for Unparalleled Productivity

High-Speed Extrusion Process

Boyu Extruder's plastic extrusion line is renowned for its exceptional speed and efficiency, setting new benchmarks for high-volume production. Featuring advanced extrusion technologies such as high-speed screws and optimized heating systems, the line enables rapid material processing, accelerating production cycles, and maximizing output.

Precision Control Systems

Precision is the cornerstone of Boyu Extruder's plastic extrusion line, thanks to state-of-the-art control systems. Automated thickness control, real-time monitoring, and temperature regulation mechanisms ensure consistent product quality while minimizing waste. Manufacturers can rely on Boyu Extruder's extrusion line for precise operation and reliable output, enhancing overall efficiency and reducing costs.

Streamlined Workflow and Efficiency

Boyu Extruder's plastic extrusion line is designed to streamline production workflows, minimizing downtime and maximizing efficiency. With features like quick changeovers, modular design, and automated material handling, the line optimizes productivity, allowing manufacturers to meet demanding production schedules with ease.

Versatility

Material Compatibility

Boyu Extruder's plastic extrusion line boasts exceptional versatility, accommodating a wide range of materials. From HDPE to PVC, PET, and more, the line is capable of processing diverse materials. This versatility enables manufacturers to cater to various industries, including packaging, construction, automotive, and beyond.

Tailored Production Specifications

Flexibility is a key feature of Boyu Extruder's plastic extrusion line. It can be customized to meet specific customer requirements, allowing for adjustments in dimensions, thickness, surface finish, and other parameters. By tailoring production specifications, manufacturers can achieve personalized solutions that align with unique needs and deliver superior products.

Superior quality and consistency

Advanced Quality Control Measures

Boyu Extruder is committed to delivering products of uncompromising quality through its plastic extrusion line. The line incorporates advanced quality control measures, including precise temperature control, uniform material distribution, and rigorous testing protocols. These measures ensure that each product meets the highest standards of quality and reliability.

Consistent output and performance

With Boyu Extruder's plastic extrusion line, manufacturers can expect consistent output and performance. The line integrates advanced monitoring systems and quality assurance protocols and adheres to stringent manufacturing standards. This commitment to consistency ensures that each product maintains the desired specifications, providing customers with reliable and superior performance.

Conclusion

Boyu Extruder's cutting-edge plastic extrusion line is the driving force behind manufacturing excellence. Through advanced technology, versatility, and an unwavering commitment to quality, Boyu Extruder empowers manufacturers to achieve unrivaled productivity and deliver exceptional products. For businesses seeking transformative plastic extrusion solutions, Boyu Extruder is the trusted partner that propels manufacturing towards excellence.