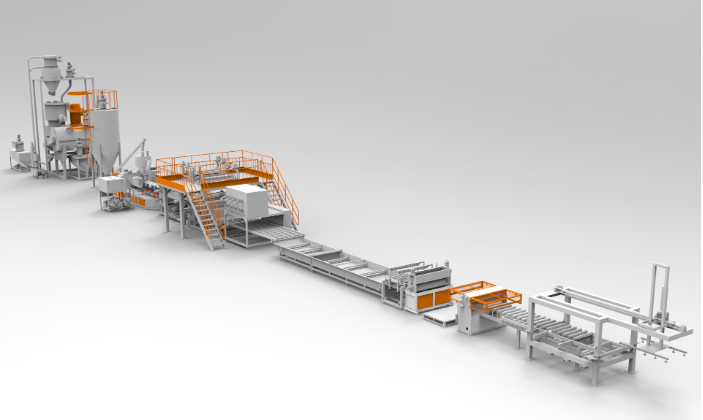

As a company specializing in producing an LVT flooring production line, Boyu focuses on technological innovation and research in product quality, environmental protection, and safety. There are seven types of equipment on Boyu¡¯s LVT flooring production line, including an extruder, T-die, calender, water tank, traction machine, cutting machine, and automatic fipping and stacker system. This article discusses the production process and advantages of Boyu¡¯s LVT flooring production line.

What Is LVT Flooring?

LVT flooring, short for Luxury Vinyl Tile, is a type of vinyl flooring. It is designed to replicate hard surface floors materials such as stone or wood. It is water-resistant and easy to clean. LVT primarily makes of polyvinyl chloride and calcium carbonate. It is used as a hard surface flooring product for commercial and residential interior applications.

LVT Flooring–producing Process

The production process of LVT flooring is not complicated, only needs the following steps to make it successful:

First, the extruder is used to plasticize and homogenize the PVC compound, which will be extruded at 180 degrees to form the LVT core board. Then the material leaving the T-die smoothly enters the downstream of the calender, and is pressed with a high-temperature platen.

The Advantages of the LVT Flooring Production Line

It is undeniable that LVT flooring has attracted more and more attention from many people. The LVT flooring production line has many advantages. The following four points are the substantial advantages that the LVT flooring production line can provide:

1. Smart control system

The traditional LVT flooring production line requires much labour and takes a long time for molding. In contrast, the machines in the new LVT flooring production line are highly advanced and computerized, which can design and make any style of LVT flooring. The smart control system of the equipment can also be changed before and after the production operation without disturbing the production process.

2. High efficiency

The modern LVT flooring production line replaces the problems of low production efficiency, large space occupied by the machine, and cumbersome operation caused by the traditional machine. This new production line can realize functions such as online compounding and tempering. In addition to flexibility and economy, the LVT flooring line extruder allows high-volume production in continuous manufacturing cycles.

3. High-quality

LVT flooring production machines equipped with high-precision capabilities. The floor produced by the LVT flooring production line is highly moisture-proof and durable. Moreover, the shears on the production line can automatically cut the strips to the required length.

4. Save labour cost

The conventional LVT flooring production line was complex and required long hours of labour to achieve high output. Today’s automated LVT flooring lines are run entirely by machines, which means that it not only saves on overall labour costs but also eliminates any risk of human error.

Boyu LVT Flooring Production Line

The LVT flooring production line can help various flooring manufacturing enterprises gain a foothold in this industry and expand their business to a global scale. But these flooring manufacturing enterprises need to cooperate with reliable plastic extruder manufacturers. Boyu, a complete plastic machinery solution provider, offers first-class LVT flooring production lines manufactured under a strict quality control system. With more than two decades of extrusion experience, Boyu can simultaneously meet a wide range of business scopes and requirements.

Boyu¡¯s LVT flooring production line has advanced functions such as waterproof safety, high efficiency, durability, and long-lasting performance. It employs a PLC-programmed control system (selectable from Omron or Siemens) paired with an intuitive touchscreen human-machine interface (HMI) sourced from renowned Chinese manufacturers or Siemens.

Additionally, the low-voltage electrical components are sourced from Schneider. The machines on the production line are certified by CE. With highly qualified technicians closely monitoring the LVT flooring production line and design department, Boyu is proud to exceed the expectations of its international clients by providing environmentally friendly solutions to their LVT flooring production line problems.

Contact us for more information about Boyu¡¯s LVT flooring production line.