Plastic extruder is valued for its outstanding production capability, speed and flexibility. According tFuture Market Insights (FMI) statistics, the global plastic extruder market reached $6.7939 billion in 2022. In 2032, it is expected to reach $10.754.4 billion.

What Is a Plastic Extruder?

Plastic extruder is highly demanded because it is the best option for the mass manufacturing process of forming ordinary plastics and thermoplastic materials. This article introduces the basics of plastic extruders, including their working process and types, and presents their applications in different industries.

Working Process of Plastic Extrusion

Plastic extrusion is a high-volume manufacturing process for melting raw plastic and forming continuous profiles. The process of plastic extrusion starts by feeding plastic material (granules, flakes, or powder) from a hopper into the barrel of an extruder. The material is melted gradually by the mechanical energy generated along the rotating screw and heater. The molten polymer is then pressed into a mold, forming a hardened shape as it cools.

Types of Plastic Extrusion Machines

Nowadays, there are various plastic extruders on the market. According to the mode of operation, it can be mainly separated into two types: Continuous extruder and discontinuous extruder. The distinction between the two is the part that moves the material. There are three main types of extruders:

1. Single-screw Extruder

Single-screw extruders are the most common type of continuous extruder. The machine consists of a single Archimedean screw rotating in a heated barrel. It is widely used because of its simple structure, high processing efficiency, and small machine size.

2. Twin-screw Extruder

The twin-screw extruder can be classified as a continuous multi-screw extruder. The machine is developed based on a single-screw extruder. Generally, the machine has good plasticizing performance, exhaust performance, and extrusion stability.

3. Multi-screw Extruder

The planetary roller extruder is a common-used machine in the multi-screw extruder. The machine has six evenly distributed screws rotating around the main screw, usually applied to rigid or plasticized PVC.

Uses of Plastic Extrusion

Utilizing plastic extrusion technology makes it more efficient in producing plastic products. Therefore, the plastic extruder is also widely used in various industries. Here are some application examples.

lPVC Pipe: PVC pipe is prevalently used in daily life. For example, PVC pipe is used to transport water into buildings in water distribution systems. In the construction industry, PVC pipe is mainly used in downspouts and drainage pipes. Furthermore, PVC pipes are also widely used as medical tubes in medical equipment.

lPVC-type Materials: PVC-type materials are also used in various fields. For instance, office partitions and decoration in office furniture products, as well as the shelves and polypropylene hinges in retail products. PVC materials are characterized by durability with low maintenance costs.

lSPC Floor: SPC floor can be easily laid without nails, glue, and keel, which is cost-effective and convenient. It does not expand and contract. Thus it is suitable for flooring.

lLVT Floor: LVT floor is mainly made of vinyl material. The floor is soft, resistant to moisture, and has a wear-resistant layer. It is suitable for furniture floor decoration and can be used in the industrial, shopping mall, and other work platforms.

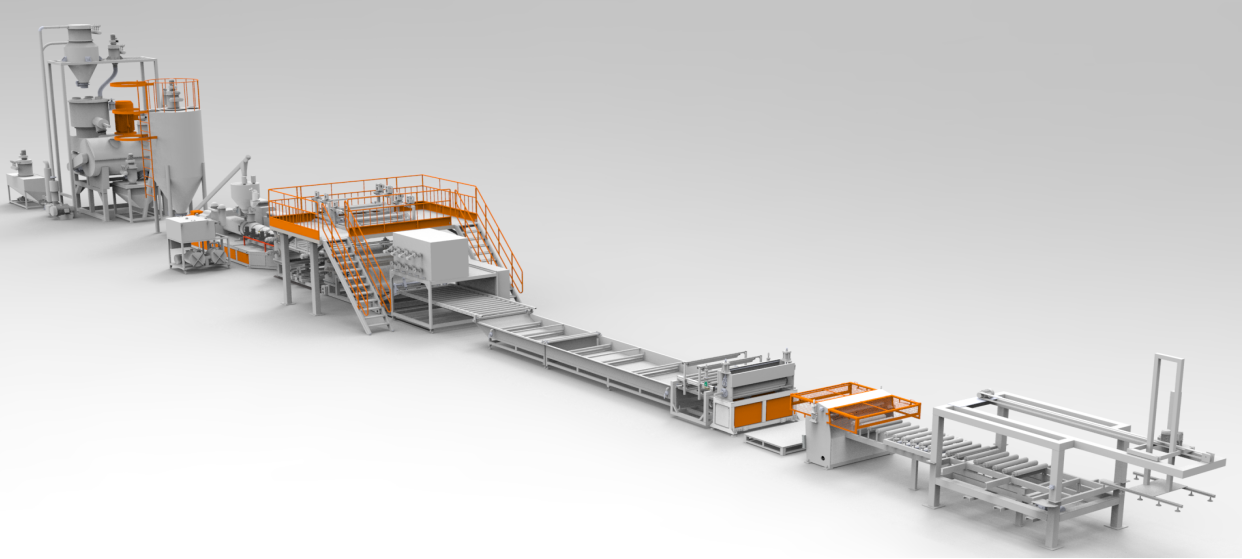

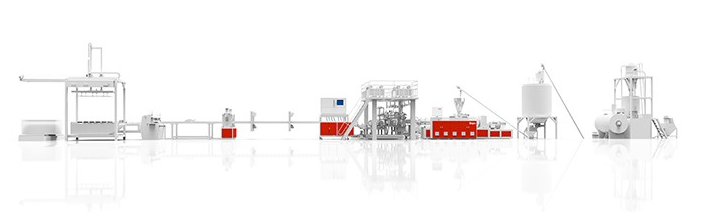

Boyu SPC, LVT Flooring Production Lines

With the advancement of technology, people are gradually becoming aware of the benefits of SPC and LVT flooring and regard them as the best alternative. However, producing such flooring requires sufficiently specialized and sophisticated machines. Boyu is a professional enterprise possessing industry-leading extrusion technology applied in SPC flooring lines and LVT flooring production lines. Boyu¡¯s SPC flooring lines and LVT flooring production lines are both equipped with high-quality conical twin-screw extruders. The two products have the advantages of high accuracy, high productivity, and low failure rate. Both products have passed the CE certification.

Contact us if you are interested in our product!