From raw material extraction and production to installation, use, and disposal, flooring has a significant impact on the environment throughout its lifecycle. With an increasing awareness of sustainable living among consumers, eco-friendly flooring options are gaining popularity. Two innovative flooring categories, Stone Plastic Composite (SPC) and Wood Plastic Composite (WPC) flooring, boast green advantages in both their manufacturing processes and final applications. In this article, we will explore sustainable flooring choices that provide style and durability while also contributing to environmental well-being.

Understanding Sustainable Flooring

Compared to traditional flooring, such as laminate or carpet, sustainable flooring aims to reduce carbon emissions. Its key environmental goals include the utilization of recycled materials, the avoidance of harmful chemicals, the reduction of waste, and the achievement of total post-use recycling. As eco-friendly flooring options, SPC and WPC flooring achieve a compromise between aesthetics and environmental responsibility.

Eco-Friendly Features of SPC Flooring Production

Calcium carbonate from limestone powder and polyvinyl chloride (PVC) are the two basic components of SPC flooring. Heating and molding these core elements under high pressure and temperature fuse them into a durable, waterproof floor. Several aspects of SPC production make it more environmentally friendly than manufacturing traditional flooring:

1. Reuse of Industrial Waste: SPC flooring, made from limestone and PVC, gives a second life to materials that might otherwise end up in landfills.

2. Lower Toxicity: Compared to traditional flooring, SPC flooring employs fewer toxic compounds during manufacturing, resulting in a healthier interior environment.

3. Durability and Moisture Resistance: The high durability and water resistance of SPC flooring not only enhance its performance but also contribute to extending the product's lifespan, reducing the need for frequent replacements.

4. Waterproof Nature: The 100% waterproof feature of SPC flooring eliminates the need for chemical adhesives during installation, further reducing its environmental impact.

5. Recyclability: SPC flooring can be entirely recycled at the end of its lifecycle, providing a sustainable solution to flooring disposal issues.

Eco-Friendly Features of WPC Flooring Production

WPC flooring combines wood fiber remnants from the wood industry with recycled plastic, bringing its own sustainability advantages. These components are extruded to create a scratch-resistant, environmentally-friendly floor. Here are some features of WPC flooring production:

1. Use of Recycled Materials: WPC flooring combines recycled wood fibers and plastic debris into its manufacturing process, decreasing raw material consumption.

2. Energy Efficiency: The extrusion method used in WPC flooring production is highly energy-efficient, minimizing its overall environmental footprint.

3. Durability and Scratch Resistance: The durability and scratch resistance of WPC flooring contribute to prolonged use, lowering the frequency of replacements and eliminating waste.

4. Installation Without Harmful Adhesives: WPC flooring is installed using a floating approach, which eliminates the requirement for glues containing Volatile Organic Compounds (VOCs) or formaldehyde, maintaining indoor air quality.

5. Minimal Emissions: The inert components in WPC flooring aid in reducing emissions and preventing the release of indoor air pollutants.

6. Recyclability: WPC flooring can be reused or recycled at the end of its life cycle, diverting it from landfills and contributing to a circular economy.

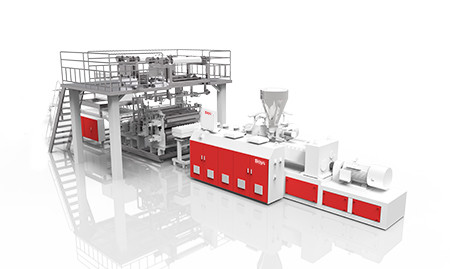

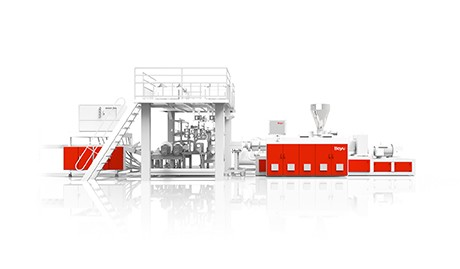

Product Recommendation: Boyu's SPC and WPC Flooring Production Lines

Boyu Extruder is a market leader in offering environmentally friendly flooring production solutions. Along with cutting-edge WPC Flooring Production Line, we offer three advanced SPC Flooring Production Lines, including SPC Conical Twin Screw Production Line, SPC Parallel Twin Screw Production Line, and SPC Building Block Twin Screw Production Line. These demonstrate our dedication to precision, efficiency, and environmental stewardship.

Our plastic extrusion machines provide accuracy and efficiency throughout production, using European extrusion technology to ensure precision in heating, mixing, molding, and cooling. Furthermore, our commitment to environmental responsibility is reflected in the design and functionality of our production lines, minimizing waste and energy consumption.

Conclusion

Emphasizing the importance of choosing sustainable flooring options cannot be overstated. As consumers, we have the ability to make choices that improve our living spaces while also positively impacting the environment. In comparison to traditional flooring, SPC and WPC flooring types offer durability and indoor air quality advantages while repurposing waste. Choosing eco-friendly flooring goes beyond personal preference; it is a step toward a more sustainable and responsible future. Contact us if you are interested in our flooring production line!

Related Articles: