Flooring plays a vital role in interior design, establishing the foundation for the aesthetics and functionality of a space. SPC flooring, also known as stone-plastic composite flooring, has become popular in recent years due tits durability, versatility, and aesthetics. SPC flooring combines the strength of stone with the flexibility of vinyl, providing resilient and visually pleasing solutions for residential and commercial spaces. In this article, we explore the flooring innovations and trends that will shape the future of SPC flooring in 2025.

Innovations in SPC Flooring

- Design versatility and aesthetics: A notable flooring innovation of SPC flooring lies in its improved design versatility. Manufacturers constantly introduce new patterns, colors, and textures, offering various design options to complement diverse interior styles. Realistic visual effects, such as replicating the look of natural wood or stone, greatly influence interior design aesthetics, resulting in visually appealing and harmonious spaces.

- Enhanced Durability and Waterproof Properties: SPC flooring takes durability to the next level. Advanced wear layers and protective coatings protect floors from scratches, stains, and daily wear and tear, even in high-traffic areas. Additionally, SPC flooring inherently possesses waterproof properties, making it ideal for moisture-prone areas like kitchens and bathrooms. It can withstand spills and humidity without warping or compromising its structural integrity.

- Eco-friendly and Sustainable Practices: The SPC flooring industry embraces sustainable practices in response to the growing demand for eco-friendly options. Manufacturers are adopting sustainable practices by using recycled materials, reducing energy consumption during production, and adopting eco-friendly manufacturing processes. Individuals can enjoy beautiful floors through these environmentally conscious advancements while minimizing their environmental impact. This shift toward sustainability aligns with the increasing consumer awareness and preference for eco-conscious choices.

Current Trends in SPC Flooring

- Wide Range of Design Options: SPC flooring offers various design options, allowing individuals to discover the ideal floor to complement their unique style. From classic hardwood looks to modern and abstract patterns, SPC flooring offers a range of options. The availability of various colors, finishes, and surface textures enables homeowners and designers to craft unique and personalized spaces.

- Thinner and More Flexible Planks: Another emerging trend in SPC flooring involves the production of thinner and more flexible planks. Thinner planks provide a sleek and modern look, while their increased flexibility facilitates easier installation, particularly on uneven or irregular subfloors. Thinner planks enable smoother transitions between different flooring materials and seamless flow between rooms or areas. This trend caters to the demand for versatile and adaptable flooring solutions.

- Noise Reduction Features: Noise reduction has become a key consideration in interior design. SPC flooring manufacturers are incorporating noise reduction features into their products, employing innovative underlayment materials and construction techniques, such as underlayment options or sound-absorbing layers, to minimize sound transmission. These advancements help create a quieter and more comfortable living or working environment, especially in multi-story buildings or high-traffic areas.

Boyu¡¯s SPC Flooring Production Lines

Boyu is a reputable manufacturer offering advanced SPC flooring production lines. Boyu¡¯s SPC parallel twin-screw production line and conical twin-screw production line ensure the efficient and high-quality production of SPC flooring.

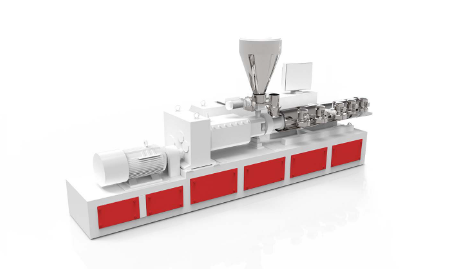

SPC Parallel Twin Screw Production Line

Boyu¡¯s SPC parallel twin-screw production line has top-notch extrusion technology to ensure precise manufacturing process control. Parallel twin-screw extruders enable efficient blending of raw materials, resulting in consistent and high-quality SPC compounds. The extrusion process ensures an even distribution of material, improving the final product¡¯s overall strength, durability, and performance. Manufacturers can create various design options with Boyu¡¯s SPC parallel twin-screw production line. Whether replicating the appearance of hardwood, stone, or a unique pattern, Boyu¡¯s SPC parallel twin-screw production line creates stunning and authentic SPC flooring designs.

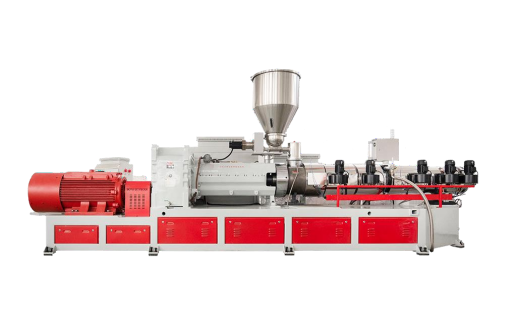

SPC Conical Twin Screw Production Line

Boyu¡¯s SPC conical twin-screw production line is equipped with the patented printed film synchronous matching system to ensure excellent control and accuracy throughout production. The conical twin-screw design optimizes material blending and ensures uniformity melting for consistent and uniform extrusion. This technology guarantees the produced SPC flooring¡¯s excellent dimensional stability, strength, and aesthetics. The production line features an advanced PLC programming system and a user-friendly touchscreen interface.These functionalities streamline the production processes, minimize downtime, and maximize yields, allowing manufacturers to meet growing market demands efficiently.

Boyu¡¯s SPC flooring production lines have obtained CE certification. By choosing Boyu¡¯s SPC flooring production line, manufacturers can provide high-quality SPC flooring that caters to the evolving market requirements.

Boyu is committed to continuous flooring innovation and offers comprehensive support to customers. They are always at the forefront of industry trends and technological advancements, ensuring their production lines incorporate the latest flooring innovations. As an industry-leading manufacturer, Boyu¡¯s SPC flooring production line contributes to producing high-quality SPC flooring, making it a reliable and highly sought-after choice for interior design projects for years to come.

Contact us for more information!

Related Articles:

The Latest Flooring Trends to Look Out for in 2025

Is SPC Floor Environmentally Friendly?