Ensuring quality, efficiency, and reliability in SPC (Stone Plastic Composite) flooring production demands a fine balance of precision engineering, optimal materials handling, robust equipment, and meticulous process control. Below, we explore five indispensable production tips designed to elevate your SPC floor production line or flooring production line operations—especially aligned with high standards and performance.

Flooring Specifications: What Really Matters

SPC flooring must meet stringent dimensional and functional standards to ensure long-term performance and user satisfaction. Below is a detailed table of critical specifications:

| Parameter | Specification | Why It Matters |

| Thickness Deviation | ±0.05 mm | Demands extreme precision in production—ensures tight seams without gaps or height differences when installed. |

| Density | 1.9–2.1 g/cm³ | Indicates a high-density structure that delivers enhanced strength, impact resistance, stability, and wear-resistance. |

| Shrinkage (80°C, 6 h) | ≤0.1 % | Excellent dimensional stability under heat—minimizes thermal expansion/contraction. |

| Warp (per meter) | ≤0.5 mm/m | Ensures surface flatness; avoids buckling or concave surface issues after installation. |

| Verticality/Straightness (≤400 mm) | ≤0.25 mm | High linearity in edge cutting guarantees tight joints. |

| Verticality/Straightness (≥400 mm) | ≤0.35 mm | Maintains alignment and accuracy over longer edge spans. |

| Slip Resistance Index | ≥0.30 mm | Provides safe usage in residential and public places—minimizes slip risks. |

| Lock Gap (Latching Precision) | ≤0.10 mm | Ensures tight lock seams—reduces water or dust ingress and enhances visual appeal and lifespan. |

| Lock Tension at 23 °C (/5 cm) | l 5 mm thick: 13–15 kg; l 4.2 mm thick: ≥12 kg; l Short edge with V lock: >15–18 kg | Demonstrates robust latching, resisting splitting or loosening under daily stresses. |

| Light Resistance | ≥ Grade 6 | Retains color over time, reducing the tendency to fade under exposure. |

| Peel Strength | ≥50 N/cm | Ensures strong interlayer adhesion—prevents delamination. |

| Thermal Conductivity | 0.25 W/(m·℃) | Ideal thermal transfer properties—suitable for underfloor heating and a comfortable foot feel. |

Production Tips: How to Boost Performance

Here are the key operational insights to elevate your SPC flooring production line:

- Maintain Continuous Production Stability

SPC lines typically involve high extrusion volumes combined with inline film-lamination. Ensuring consistent operation is vital to avoid downstream defects or interruptions.

- Optimize Screw Lifecycle

SPC formulations are highly filled, increasing wear on the twin‐screw extruder. Given the high cost and critical performance dependence, prolonging screw life through proper materials handling and maintenance significantly lowers your total operational cost.

- Prioritize Raw Material Flowability

With slim board thickness tolerances and fast extrusion speeds, superior material dispersal, plasticizing, and flow behavior are critical. Focus on raw material quality and precise screw design to deliver tight tolerances and avoid surface defects.

Equipment Tips: Invest Smart, Run Efficiently

High-precision SPC production relies on top-tier machinery. Here’s what to aim for:

- Durable, low-wear extruder screws and barrels—ensuring low pressure and effective plasticization.

- Even-output die—and mold design—for uniform sheet formation.

- Accurate multi-roll calendering system—simple to adjust and tightly controlled for thickness accuracy.

- Precise film-guidance, tension-control, and edge-correction systems—critical for overlay lamination without wrinkling or misalignment.

- Sufficient cooling zone and capacity—ensures dimensional stability and mitigates warping.

- Carefully engineered cutting and handling systems—that avoid surface damage or deformation.

- Machine sizing aligned with board thickness range—avoid chasing throughput at the expense of suitability.

Calender Lamination Process: Get the Controls Right

With extrusion stable, the calender-adhesion process is where precision meets finesse. Here’s how to nail it:

- Control Nip Gaps, Temperatures, and Speeds Precisely

The first roller pair defines board thickness and is set based on extrusion line speed. The second, film-applying pair must run slightly faster to create mild tension—enough for good adhesion but not enough to stretch or narrow the film.

- Balance Traction Speed

Ensure synchronization; too fast can warp the board, too slow may cause wrinkles. Adjust based on real-time line behavior.

- Optimize Embossing and Lamination

Nip pressure, temperature, and gap determine embossing clarity and film adhesion. Adjust according to board thickness and film type, always considering how traction speed affects results.

- Typical Roller Temperature Range

Between 165–185 ℃, ensuring proper calendering, embossing distinctness, strong adhesion, clean edge trimming, and undistorted film.

- Uniform Gap Across Both Roller Pairs

Ensure consistency through coordinated adjustments for stable thickness and texture.

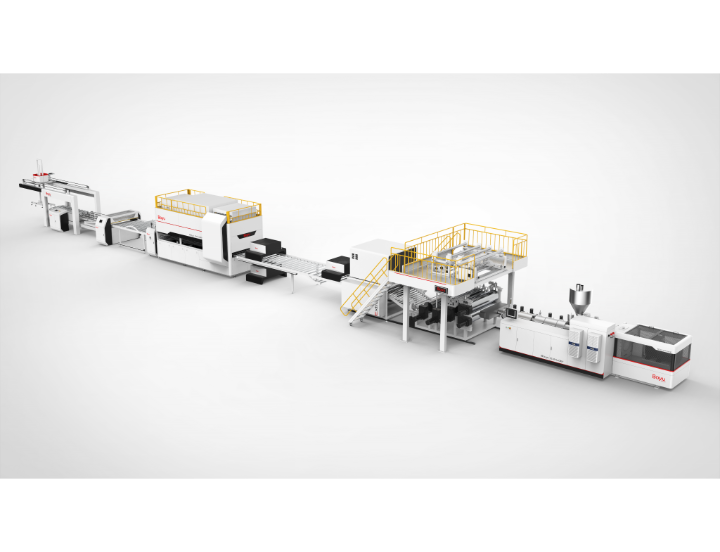

Boyu SPC Flooring Extrusion Line

For manufacturers seeking a reliable and advanced turnkey solution, the Boyu SPC Flooring Extrusion Line stands out:

- Employs high-quality conical twin-screw extruders, delivering high precision and performance in SPC flooring production.

- Features an intelligent PLC + touch-screen interface, giving automation, precise control, and ease of operation.

- Offers models tuned to production needs:

- SZJZ-80: 6–8 t/day, ~0.4–0.6 m/min

- SZJZ-92: 12–18 t/day, ~0.8–1.3 m/min

- SZJZ-110: 25–32 t/day, ~1.8–2.4 m/min

- SZJZ-180: 70–100 t/day, ~5–9 m/min.

- Prioritizes energy efficiency, high productivity, stable and reliable operations, and low failure rates.

Conclusion

Mastering SPC flooring production hinges on:

- Meeting precise material and performance specs.

- Ensuring stable, optimized production processes.

- Investing in robust, well-matched equipment.

- Managing the calender lamination process with finesse.

- Choosing partner solutions like Boyu’s SPC flooring extrusion line for turnkey effectiveness.

With these five essential tips, you’ll be well-equipped to navigate the challenges of high-precision SPC flooring manufacturing—boosting quality, efficiency, and competitiveness.