Choosing new flooring is an exciting yet challenging task. With so many various types of flooring available, how do you know which one is best for your new home? Nowadays, WPC (Wood Plastic Composite) flooring and classic solid wood flooring have become two common options for many consumers. Both have unique advantages that appeal to users but differ significantly. In this article, we will delve into the WPC vs wood flooring comparison to help you make the best decision for your home.

WPC Flooring Overview

WPC flooring has grown in popularity over the last decade due to its resilience and low cost. It combines wood fibers with plastic resins, creating a durable, scratch-resistant, and environmentally friendly composite material. The mixture of wood-patterned and textured plastics mimics the design of natural hardwood, spanning various styles from oak to exotic tropical woods.

Another key benefit of WPC flooring is its easy installation. These planks typically feature a click or floating system, allowing for a simple DIY installation without the need for nails or glue. The combination of various materials gives WPC flooring inherent durability and water resistance, making it an excellent choice for high-moisture areas such as kitchens, bathrooms, and basements.

Solid Wood Flooring Overview

Solid wood flooring, on the other hand, is always a classic choice. It's composed mostly of natural hardwood single boards like oak, maple, and walnut, emitting timeless beauty with its authentic wood patterns and grains. However, it's crucial to consider the environmental impact of solid wood flooring. The production of solid wood flooring requires logging large quantities of trees, which might lead to deforestation and depletion of natural resources. This disrupts ecosystems and increases carbon emissions associated with logging and transportation.

Furthermore, solid wood is softer than rigid wood-plastic composite material, making it more prone to dents and scratches. Its higher upfront costs and a more labor-intensive installation process requiring skilled professionals contribute to its complexity. If not properly maintained, natural materials are also susceptible to dents, scratches, and permanent damage due to prolonged water exposure.

WPC vs Wood Flooring: The Ultimate Comparison

1. Cost: Because of its wood-plastic combination, WPC flooring is often 50-75% less expensive than solid wood flooring. However, it may require more frequent replacement than solid wood.

2. Installation:WPC flooring, with its click installation system, requires no glue or fasteners, making it suitable for DIY projects. During the installation of solid hardwood, competent nailing, stapling, and gluing are required.

3. Durability: WPC flooring excels in scratch, stain, dent, and water damage resistance, while solid wood requires more careful protection.

4. Styles: WPC offers a wide range of colors and patterns to meet different design preferences. At the same time, solid wood possesses the natural, unparalleled beauty of natural wood.

5. Eco-Friendly: WPC flooring demonstrates environmental consciousness by utilizing wood and plastic waste, whereas solid wood requires logging more trees.

What You Should Know About Boyu's WPC Flooring Production Line

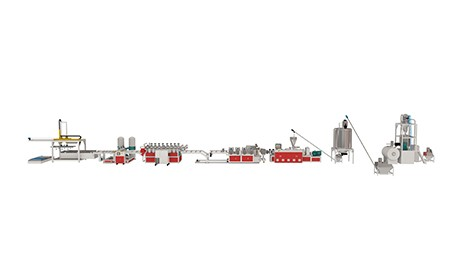

Through the above content, you now have a rough idea of whether to choose WPC or solid wood flooring. For consumers seeking durable and easy-to-install WPC flooring, WPC flooring produced by Boyu's WPC Flooring Production Line is the best choice. Our flooring production line integrates and develops various cutting-edge equipment, providing a guarantee for producing high-quality WPC flooring. Among the highlights are:

1. High-Quality WPC Extruders: Boyu's patented precision extruders blend PVC powder and calcium carbonate efficiently.

2. Comprehensive Production Capabilities: Boyu provides fully integrated production, from mixing and extrusion to embossing and cutting.

3. Precision and Efficiency: Advanced computer control optimizes every workflow stage.

4. Reliability and Support: All equipment and electrical components are CE certified, ensuring the production line runs precisely 24/7.

Currently, we have installed hundreds of WPC flooring production lines for a wide range of customers throughout the world. Our dedication to innovation, efficiency, and quality ensures the success of your WPC flooring manufacturing projects.

In short, when choosing new flooring, you can compare various WPC and solid wood flooring aspects based on the above content. Boyu's comprehensive WPC flooring production line solution provides enduring and visually beautiful quality for economically friendly, durable, easy-to-install, and stylistically diversified WPC flooring. If you are interested in our flooring production line, feel free to contact us!

Related Articles:

Exploring the Versatility of WPC Flooring in Various Applications

The Four Business Philosophies Leading Boyu to Success

What You Need to Know About Boyu's R&D Team and Innovative Technology