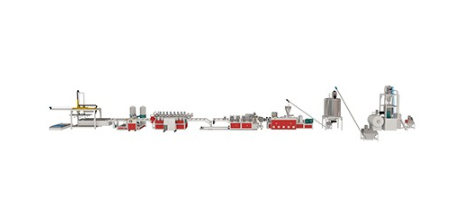

The PVC foam board production line is a crucial component in the manufacturing process, determining the efficiency, quality, and versatility of the final product. Boyu Extruder, a renowned brand in the industry, has revolutionized the PVC foam board production line with our cutting-edge technology and commitment to excellence. With Boyu Extruder's state-of-the-art machinery and equipment, businesses can optimize their production capabilities and achieve exceptional results in PVC foam board manufacturing.

The benefits of PVC foam board production

The advantages of a PVC foam board production line are numerous, making it a popular choice in various industries. PVC foam boards are highly versatile and find applications in sectors such as construction and furniture manufacturing. The production line's efficiency and cost-effectiveness are paramount, as it allows businesses to streamline their manufacturing processes, reduce costs, and maximize productivity. Moreover, the line ensures consistency and quality control in the output, delivering superior PVC foam boards that meet the stringent requirements of diverse applications.

Advanced Technology and Innovative Features

Boyu Extruder's PVC foam board production line incorporates advanced technology and innovative features, positioning it at the forefront of the industry. Ourstate-of-the-art machinery and equipment are designed to optimize the entire production process, ensuring efficient and high-quality output. With precision control systems, Boyu Extruder enables businesses to achieve optimal performance by closely monitoring critical parameters such as temperature, speed, and thickness. This level of control guarantees consistency in foam board production, resulting in superior product uniformity and meeting the highest industry standards.

The key aspect of Boyu Extruder's PVC foam board production line:Customization

Customization is a key aspect of Boyu Extruder's PVC foam board production line. Recognizing that different industries and projects have unique requirements, Boyu Extruder offers a range of customization options. From board thickness to size and surface finish, the production line can be tailored to meet specific needs, allowing businesses to produce foam boards that perfectly match their intended applications. This flexibility empowers manufacturers to create customized solutions and differentiate themselves in the market.

Quality assurance is no need to worry

Quality assurance is a top priority for Boyu Extruder in PVC foam board production. We implements rigorous quality control measures throughout the manufacturing process, ensuring that only superior products are delivered. Compliance with industry standards and regulations is at the core of Boyu Extruder's approach, guaranteeing the safety, durability, and reliability of the PVC foam boards produced. With Boyu Extruder's production line, businesses can have confidence in the longevity and reliability of their foam board manufacturing operations.

Conclusion

In conclusion, Boyu Extruder's advanced PVC foam board production line is a game-changer in the industry, empowering businesses to achieve remarkable results. With cutting-edge technology, precision control systems, and a commitment to quality, Boyu Extruder has become a trusted partner for companies seeking excellence in PVC foam board manufacturing. By investing in Boyu Extruder's production line, businesses can optimize their production capabilities, enhance product quality, and meet the demands of diverse applications, ultimately positioning themselves for success in the competitive market.