When it comes to the extrusion process, defects can pose significant challenges for manufacturers. These defects not only impact production efficiency but also compromise the quality of the final product. Understanding the criticality of addressing defects in the extrusion process, Boyu Extruder, a trusted name in the industry, has developed advanced solutions to overcome these issues effectively. With Boyu Extruder's cutting-edge machinery, precision control systems, and expert support, businesses can successfully navigate and conquer the challenges associated with defects in the extrusion process.

Definition of extrusion defects

In the extrusion process, several common defects can arise due to various factors, including material properties, process parameters, and equipment setup. One such defect is melt fracture, which occurs when irregular flow patterns in the polymer melt result in surface imperfections on the extruded product. Dimensional inconsistencies are another challenge, manifesting as variations in extruded profiles that can affect product performance and assembly. Additionally, surface imperfections such as scratches, lines, or roughness can mar the aesthetic appeal and overall quality of the final product.

How do we solve the extrusion defect£¿

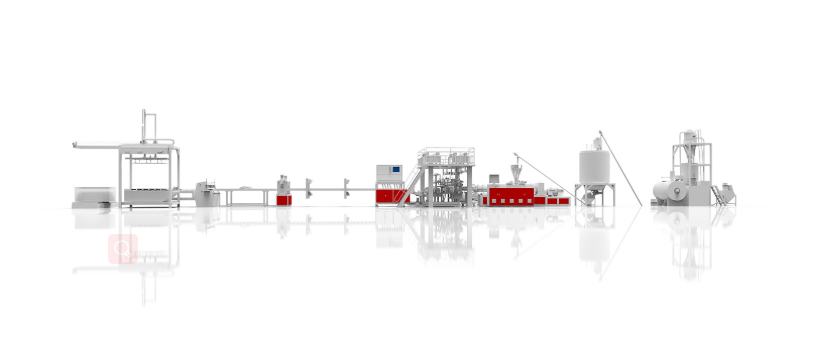

Boyu Extruder's commitment to excellence is evident in our comprehensive solutions designed to tackle defects in the extrusion process. We offers state-of-the-art extrusion machinery and equipment, incorporating the latest technological advancements. These advanced systems empower manufacturers with precise control over critical process parameters like temperature, speed, and pressure, thereby minimizing the occurrence of defects and ensuring consistent, high-quality output. Boyu Extruder's precision control systems play a pivotal role in optimizing the extrusion process and mitigating defects. By closely monitoring and adjusting key parameters, manufacturers can achieve optimal conditions for extrusion, reducing the likelihood of defects such as melt fracture, dimensional inconsistencies, and surface imperfections. The precise control offered by Boyu Extruder's systems ensures uniform product dimensions, enhanced surface finish, and improved product performance.

Perfect defect free production

In addition to advanced machinery and precision control systems, Boyu Extruder provides expert support and troubleshooting services. Our team of experienced professionals is well-equipped to promptly identify and address defects in the extrusion process. Whether it's analyzing process data, recommending adjustments, or providing technical guidance, Boyu Extruder's experts ensure that manufacturers receive the necessary support to overcome defects efficiently. This invaluable assistance helps businesses optimize their extrusion processes, minimize downtime, and achieve defect-free production.

Conclusion

In conclusion, defects in the extrusion process can present formidable challenges for manufacturers. However, Boyu Extruder's advanced solutions offer a path to overcome these obstacles and achieve remarkable results. With cutting-edge machinery, precision control systems, and expert support, businesses can effectively address defects and elevate their extrusion processes to new heights of excellence. By choosing Boyu Extruder as a trusted partner, manufacturers can rely on reliable operations, minimized defects, and superior product quality. Embracing Boyu Extruder's innovative technologies and unwavering commitment to continuous improvement, businesses can unlock the full potential of their extrusion processes, ensuring optimal productivity, reduced costs, and heightened customer satisfaction. Let Boyu Extruder be your partner in conquering defects and achieving excellence in the extrusion process.