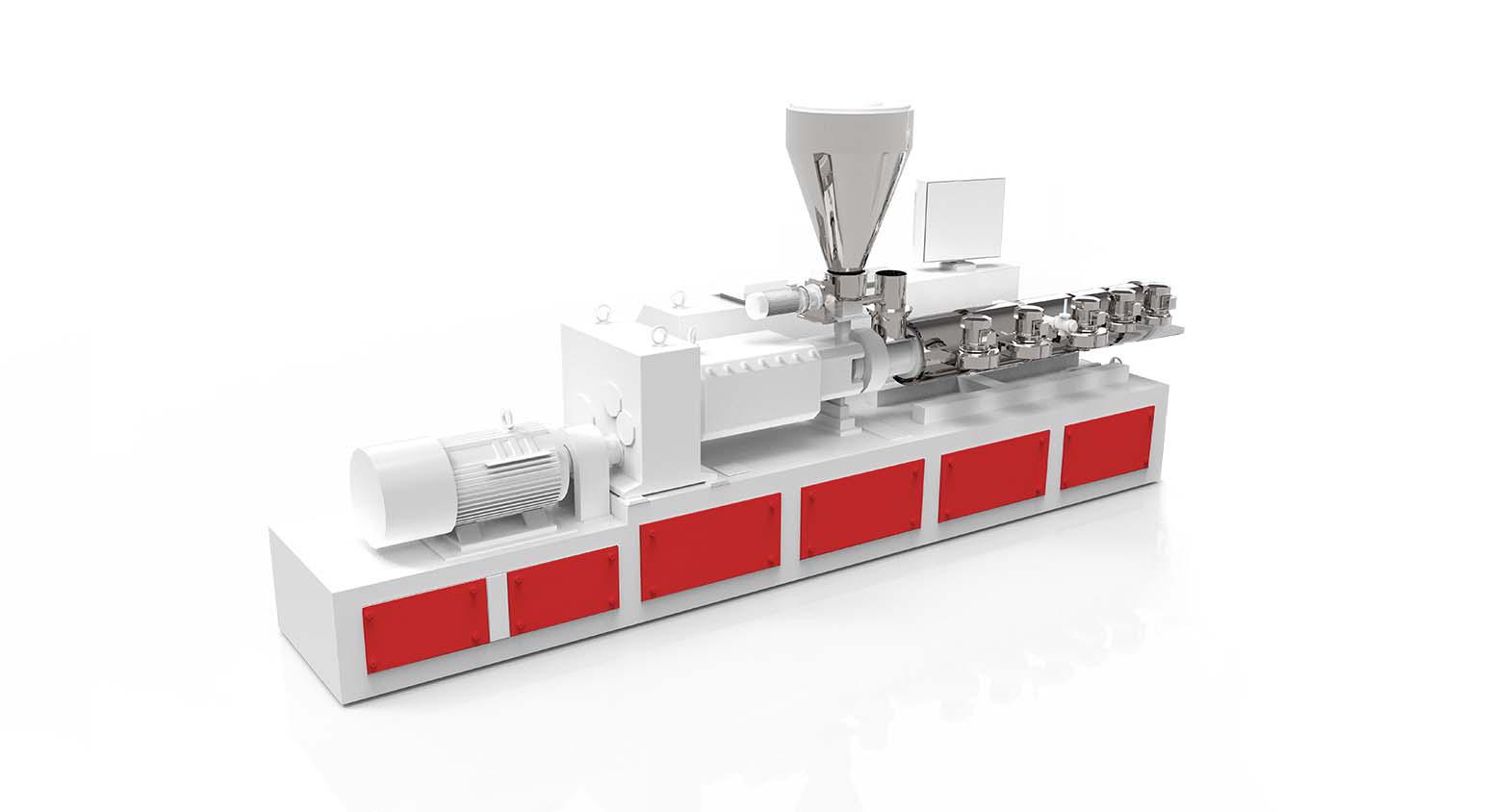

Welcome to the fascinating world of plastic extrusion! Have you ever wondered how everyday objects like pipes, tubes, and even packaging materials are made? Look no further than Boyu Extruder's state-of-the-art plastic extrusion line. Step into our factory as we take you on a journey from raw materials to finished products, unraveling the secrets behind this versatile manufacturing process.

Benefits of Boyu Extruder¡¯s Versatile Plastic Extrusion Line

Boyu Extruder's versatile plastic extrusion line has a number of benefits that make it an ideal solution for many manufacturing applications. First, the extrusion line is able to produce a wide range of products from a variety of raw materials. This makes it possible to create custom products that meet the specific needs of each customer. Additionally, the extrusion line is highly efficient and can produce large quantities of product in a short amount of time. The extrusion line is very versatile and can be used to create a variety of different products.

Automation and Control for Efficiency

In any manufacturing process, there are always opportunities for automation and control to improve efficiency. The Boyu Extruder plastic extrusion line is no different. By automating certain aspects of the production process, we can not only improve the quality of our products but also increase our production speed and efficiency.

One area where we have made great strides in automating our production process is in the area of material handling. We have developed a system that can automatically load and unload raw materials from our extruders. This has greatly reduced the amount of time needed to set up and operate our machines.

Another area where we have automated our production process is in the area of quality control. We have developed a system that can automatically inspect our products for defects. This helps us ensure that only the highest quality products leave our factory floor.

By automating these and other aspects of our production process, we have been able to greatly improve our efficiency and productivity. This has allowed us to offer our customers better quality products at a lower price.

Quality Assurance During Production

At Boyu Extruder, quality assurance is an ongoing process that begins with the selection of raw materials and continues through every stage of production. Our extrusion line is designed to produce finished products that meet or exceed our customers' expectations in terms of quality, performance, and durability.

To ensure that our products meet the highest standards, we use state-of-the-art equipment and employ a team of highly skilled workers. We also have a dedicated quality control department that carries out regular inspections at every stage of production.

Conclusion

Boyu Extruder's plastic extrusion line is an incredibly versatile tool for producing high quality, custom-made products. It can be used to turn raw materials into a variety of finished products, from pipes and tubes to sheets and profiles. With its flexibility and efficiency, it has become an important part of the manufacturing process for many industries worldwide.