Plastic extrusion is a process where plastic materials are melted and shaped into a continuous profile. This method is vital in manufacturing, producing everything from pipes to sheets and films.

However, like any intricate process, it has its share of challenges. Even with its effectiveness, plastic extrusion can encounter common issues that can impact production quality and efficiency. This article will explore common problems in plastic extrusion and provide solutions. Keep reading!

Identifying Common Plastic Extrusion Problems

Screw Cracks

Screw cracks are a common issue in the plastic extrusion process, often resulting from high pressure or poor maintenance. These cracks can cause disruptions in the material flow, leading to inconsistent product quality and increased wear on the extrusion equipment.

Film Blocking

Film blocking occurs when layers of plastic film stick together, making it difficult to separate them. This issue is typically caused by uneven material flow or cooling problems during the plastic extrusion process. Film blocking can lead to wasted materials and reduced production efficiency.

Die Build-up

Die build-up occurs when material residue accumulates on the die during extrusion, affecting the quality of the output. This build-up can lead to imperfections, such as rough surfaces or inconsistent dimensions, in the final product.

Surface Defects

Surface defects, such as lines and imperfections, are common challenges in plastic extrusion. These defects can result from temperature inconsistencies, material impurities, or improper machine settings, affecting the appearance and functionality of the final product.

Poor Extrusion Output

Poor extrusion output is a common issue that can arise from various factors, such as suboptimal screw speed, improper temperature settings, or inadequate maintenance. This problem can lead to reduced production efficiency and compromised product quality.

Practical Solutions for Extrusion Issues

Fortunately, these extrusion issues can be solved. Here are some solutions:

Addressing Screw Cracks

To avoid cracking of screws, operators must operate the extrusion machine within recommended pressure limits. Screw wear and tear can be minimized through proper maintenance, such as cleaning and lubrication, at regular intervals. Employment of high-quality, long-life materials for the screws reduces the chances of crack appearance.

Preventing Film Blocking

To eliminate film blocking, careful cooling must be done. Ensure the settings for cooling are consistent and appropriate for the material being extruded. This can also be maintained by monitoring the flow of material through an extrusion machine for even thickness to avoid blocking.

It is also helpful to use anti-blocking agents in the extrusion process. These agents reduce the friction between layers, making it easier to separate the film without causing damage.

Minimizing Die Build-up

Regularly cleaning the extrusion die will minimize die build-up. Using anti-stick coatings on the die surface can also help prevent material from adhering. Ensuring that the plastic material is free from impurities will further reduce the likelihood of build-up.

In addition to regular cleaning, using high-quality raw materials can help minimize die build-up. By reducing the impurities in the material, the risk of residue accumulating on the die can be reduced.

Improving Surface Quality

Temperature stability in the process of extrusion plays an important role in achieving better surface quality. In addition, it is worth remembering to check the purity of the raw material constantly and to readjust machine settings for better performance.

Enhancing Extrusion Output

First of all, to increase extrusion output, it would be necessary to optimize the speed of the screw to meet consistent material flow. Besides this, regular calibration of the temperature settings and periodic routine maintenance of the extrusion machine will also contribute to continued top performance.

Choosing Reliable Extrusion Equipment

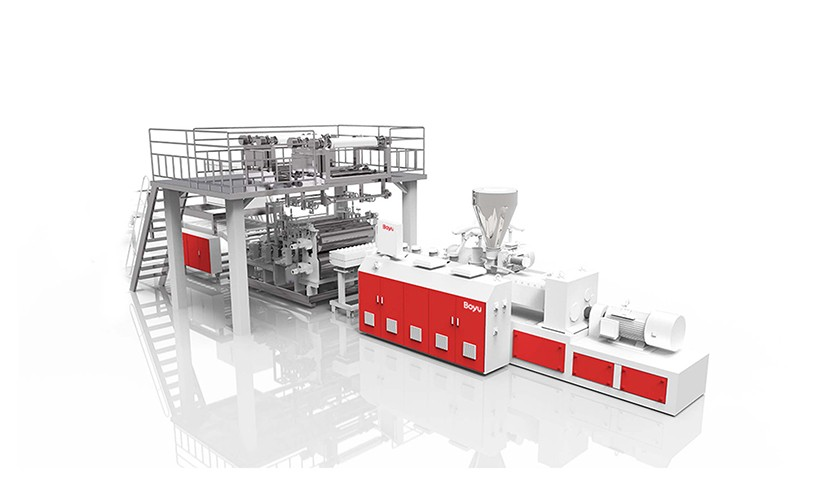

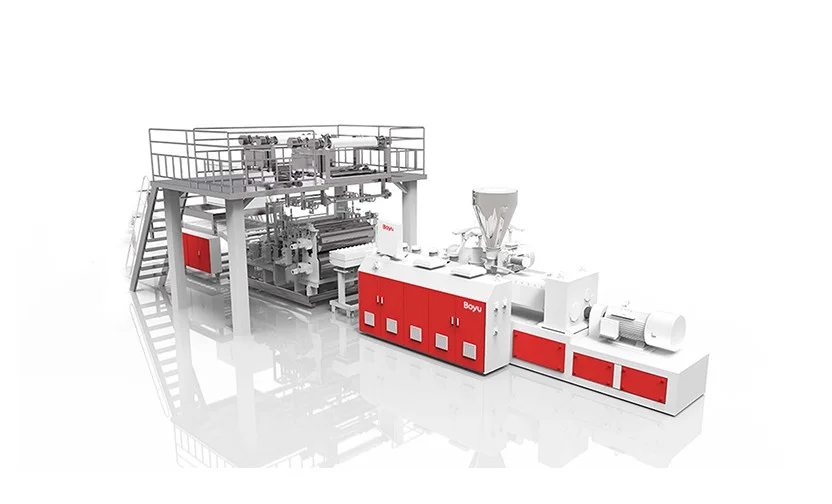

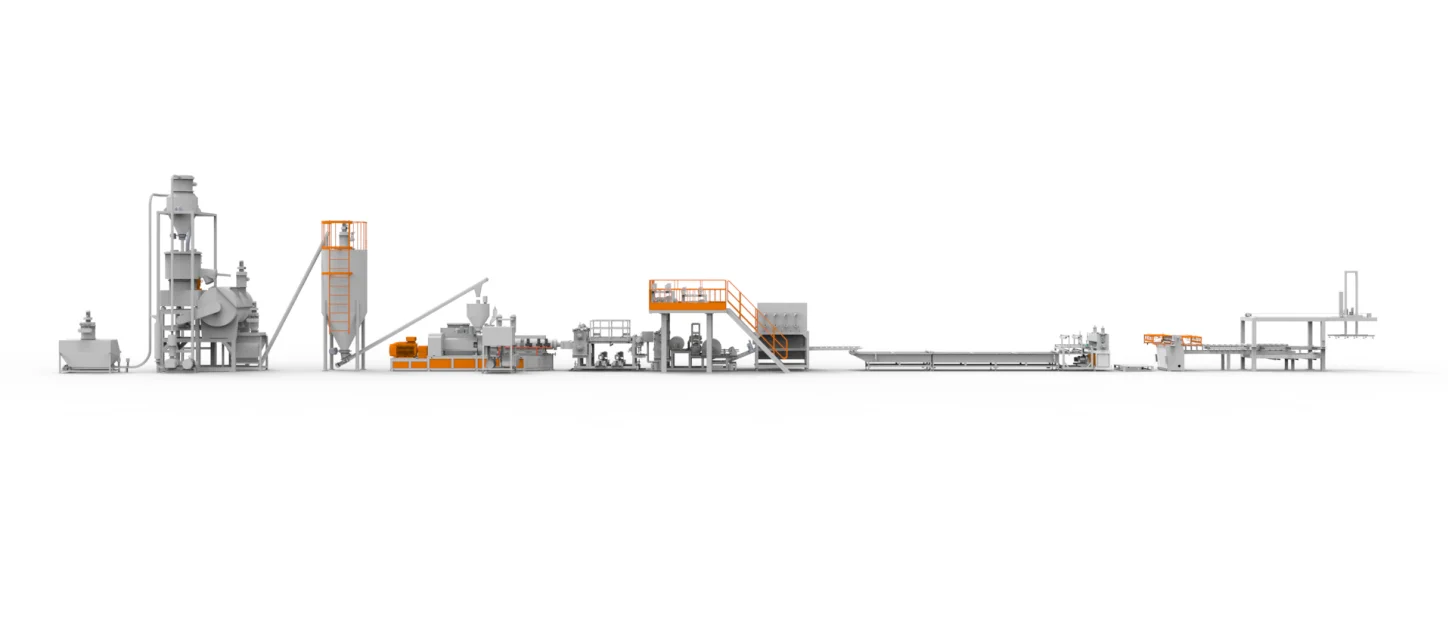

When addressing plastic extrusion problems, choosing the right equipment plays a crucial role. As a reputable name in the industry, we at Boyu offer plastic extrusion solutions tailored to meet diverse manufacturing needs. Our Boyu extruder screw crack proof controling software and Boyu setting table film blocking proof software help greatly reduce these extrusion problems. Also, all of our extrusion machines are certificated by CE, ensuring operation safety.

With our top-notch plastic extrusion machines, there will be fewer plastic extrusion problems that bother you. Thus, it is easy to deliver high-quality SPC flooring, LVT flooring, and other flooring with our twin screw extruders. Visit our website now to learn more about Boyu!