Wood plastic composites (WPC) are reversibly recyclable, multi-purpose, green, and environmentally friendly materials primarily made from wood or cellulose-based materials and plastics.

In practical applications, WPC can be produced into products with varying properties and shapes based on user and market needs. Since the 1990s, WPC has been used as a solid wood alternative in various fields.

1. Classification, Properties, and Applications

WPC can be categorized by raw material, such as polyethylene, polypropylene, polyvinyl chloride, ABS plastic, and plasticized wood. Product forms include wire, profiles, boards, sheets, and special-shaped materials. Manufacturing processes include low-foaming, medium-foaming, hollow structures, and solid materials. Based on performance, WPC can be categorized into structural, decorative, and specialized types.

Because WPC combines the characteristics of both wood and plastic, it possesses the following excellent properties:

- It is insect-resistant, corrosion-resistant, and aging-resistant, has low water absorption, will not deform due to water absorption, and has a long lifespan.

- It has a similar appearance to wood materials, with better dimensional stability than wood, and will not develop defects such as cracks and warping. It also has no wood scars and offers similar secondary processability to wood, allowing it to be cut, pasted, and fastened with hardware.

- The product’s surface is smooth, flat, and durable, and can be embossed into three-dimensional patterns and other desired shapes. By adding various colorants or coatings, it can produce a variety of colorful products with excellent decorative effects.

- It is harder than plastic, has the processability of thermoplastics, is reusable and recyclable, and biodegradable, making it environmentally friendly.

2. Applications in Furniture

In recent years, with growing environmental awareness and the intensification of energy shortages, WPC has gradually become a material for furniture manufacturing, garnering global attention. The development of eco-friendly wood furniture has become inevitable. This study of WPC’s characteristics and current applications in the furniture market focuses on the following areas:

Outdoor Furniture

Due to WPC’s strong aging resistance, eco-friendly wood furniture has a long service life outdoors. From an economic perspective, WPC offers low wear, requires no paint, and is maintenance-free. Consequently, eco-friendly wood outdoor furniture has gained recognition in many countries and is gradually replacing wood in outdoor furniture.

Bathroom Furniture

WPC’s excellent waterproof and insect-resistant properties give it unique performance in humid environments, significantly accelerating the development of eco-friendly wood bathroom furniture. Currently, WPC is primarily used in bathroom furniture such as sauna rooms, bathtub racks, washbasin racks, changing cabinets, and dressing benches.

Kitchen Cabinets

WPC’s excellent waterproof properties, flame retardancy, oil-resistance, easy cleanability, and non-toxicity have earned it a niche in high-priced kitchen cabinets. As its widespread use continues, it’s predicted that eco-friendly wood kitchen cabinets will become a future trend in kitchen cabinet furniture.

Tables and Stools

WPC offers the texture and beautiful grain of natural wood, a lower bending temperature than wood, and can be easily curved. It can also be connected with hardware, opening up new possibilities for eco-friendly wood furniture design.

3. Applications in Interior Decoration

Currently, people’s requirements for interior decoration are becoming increasingly sophisticated, and wood materials are no longer limited to living rooms and bedrooms. To meet people’s desire for nature and a return to nature, WPC is finding increasingly diverse applications in interior decoration.

Decorative Mouldings and Decorative Panels

Eco-wood decorative mouldings and decorative panels have all the installation properties of wooden decorative panels and strips, but are formaldehyde-free. They are environmentally friendly and have passed national environmental protection agency testing, completely eliminating the problems of decoration pollution and toxic gases. They also offer a strong wood feel and can be printed to the color and grain of various wood species, eliminating the worry of color variations.

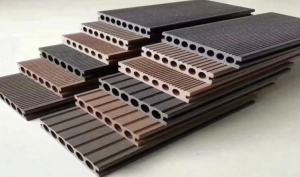

WPC Flooring

Internationally regarded as a 21st-century innovative technology, polymer ecological wood flooring combines healthy and comfortable living, environmental friendliness, stylish aesthetics, and convenient renovation. It has quickly gained popularity among decorators and homeowners, becoming a staple in interior decoration.

WPC flooring offers excellent performance, including moisture and water resistance, acid and alkali resistance, odorlessness, fungus inhibition, anti-static properties, moth resistance, and paint-free operation. It is used not only in homes but also in some public spaces.

Ecological Wood Doors and Windows

Ecological wood doors and windows feature quick-installation, saving time and effort. Various wood grain films can be printed on the surface of these doors. Available in a variety of wood types, such as cherry, alder, and ash, these doors can be finished in a variety of colors. These products offer a realistic, real-wood feel while also being water-resistant, rot-resistant, moth-proof, mildew-proof, soundproof, heat-insulating, flame-retardant, and environmentally friendly.

This is just one example of WPC’s applications in the furniture and interior decoration industries. As a new composite material, it has brought new opportunities to these industries.

With the increasing recognition and use of ecological wood composite materials, the application of these environmentally friendly materials in furniture and interior design will offer new functions and meanings, and their application prospects will be even broader.