Plastic extrusion is a versatile manufacturing process that relies on an essential component known as the die. This unique tool shapes materials into fixed cross-sectional profiles with precision and efficiency. Boyu Extruder, a leading provider of PVC floor extrusion production lines, understands the importance of optimized plastic extrusion die design. In this article, we explore Boyu's expertise and innovative solutions for three types of plastic extrusion die designs: blown film extrusion, pipe/tubing forming die, and more.

Blown Film Extrusion Die Design

For the production of shopping bags and continuous sheeting, blown film extrusion is the go-to process. Boyu Extruder offers a range of plastic extrusion die designs tailored to specific film quality requirements and polymer melt characteristics. Let's explore the three key die designs:

1. Spider Die:

The Spider die is a complex design featuring an internal mandrel connected to the outer die wall through multiple "legs." While this design may result in weld lines in the film, they are weaker compared to surrounding polymer and have distinct optical characteristics. However, the nonuniform pressure gradient caused by the spider legs can lead to uneven die swell and thicker film.

2. Crosshead Die:

The Crosshead die simplifies the flow by dividing the melt flow into two parts at the manifold inlet and recombining them opposite a cylindrical center mandrel. Although this design is relatively simple, it may result in non-symmetrical flow as molecules take longer to reach the opposite side of the mandrel. To minimize nonuniformity, varying inlet diameters and specialized inserts are employed.

3. Spiral Die:

Boyu Extruder's Spiral die is the most intricate design, distributing polymer melt into several feed tubes that wind around a central mandrel. As the feed tubes spin, their diameters gradually decrease, while the space between the mandrel and outer die walls expands. This intricate process ensures a uniform melt profile without weld lines, promoting optimal blending and layering of the polymer melt.

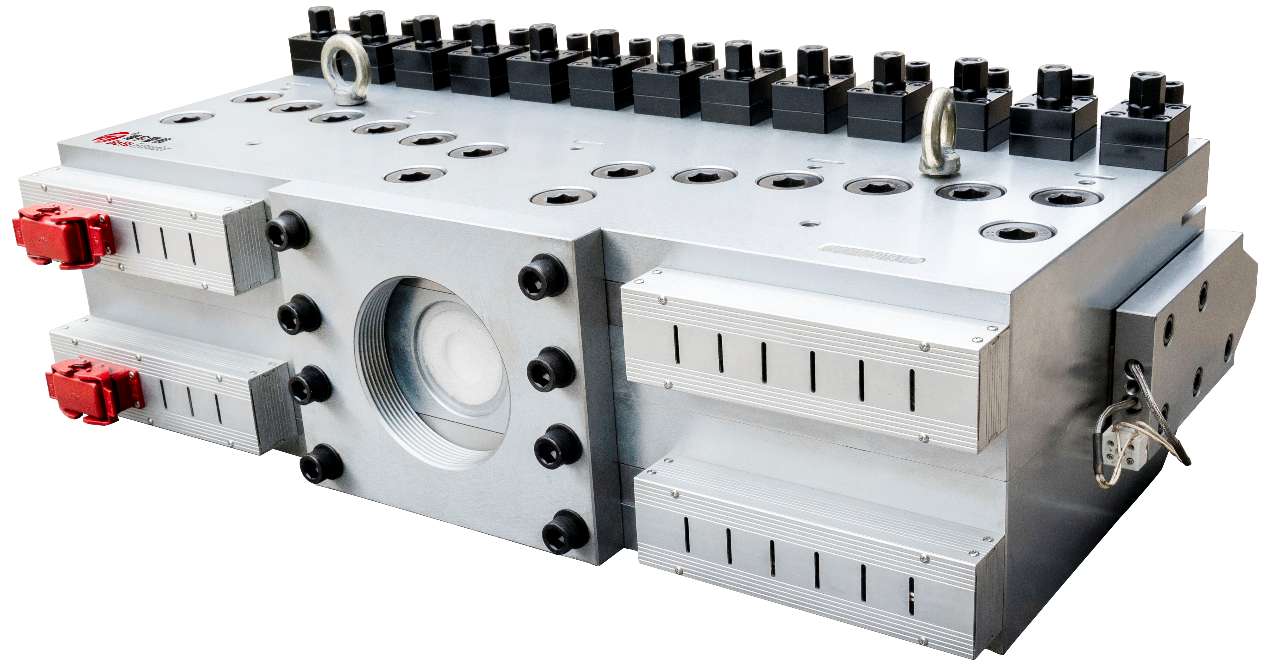

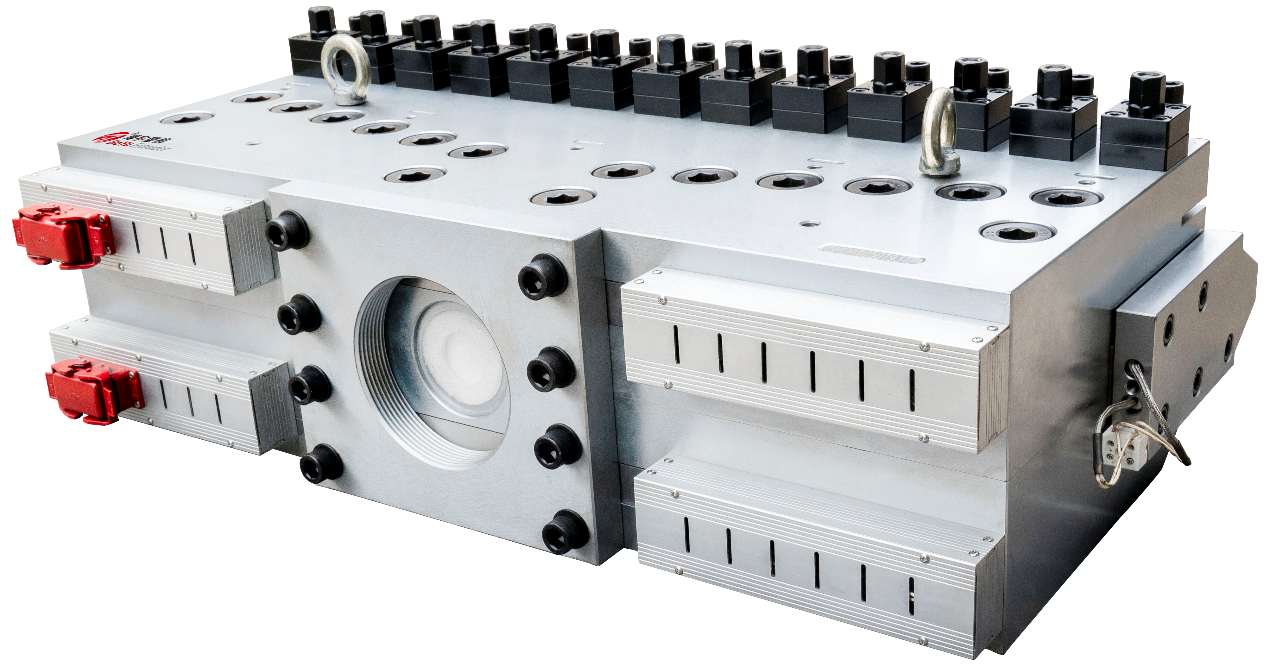

Pipe/Tubing Forming Die:

Boyu Extruder also offers plastic extrusion die designs specifically for tube and pipe forming. With similarities to blown film extrusion, this design caters to continuous extrusion of thick-walled tubes. The cooling process is often completed using water baths or cooling fans. Flexible tubes are wound onto spools, while stiff tubes are cut into preset lengths and stacked.

Why Choose Boyu

Boyu Plastic Machinery Co., Ltd. stands out as a trusted partner for PVC floor extrusion production lines. With a strong emphasis on technological innovation, environmental protection, and safety, Boyu is committed to providing user-friendly, eco-friendly, and safe equipment. Our extensive knowledge and practical experience in plastic extrusion die design ensure that we deliver optimized solutions to meet diverse manufacturing requirements.

Conclusion

When it comes to plastic extrusion die design solutions, Boyu Extruder remains at the forefront of innovation and reliability. Our expertise in blown film extrusion, pipe/tubing forming die, and more allows us to cater to specific production needs. By choosing Boyu as your partner, you gain access to advanced technology, exceptional quality, and comprehensive support. Connect with Boyu today to explore our range of plastic extrusion die designs and experience excellence in your extrusion manufacturing process.