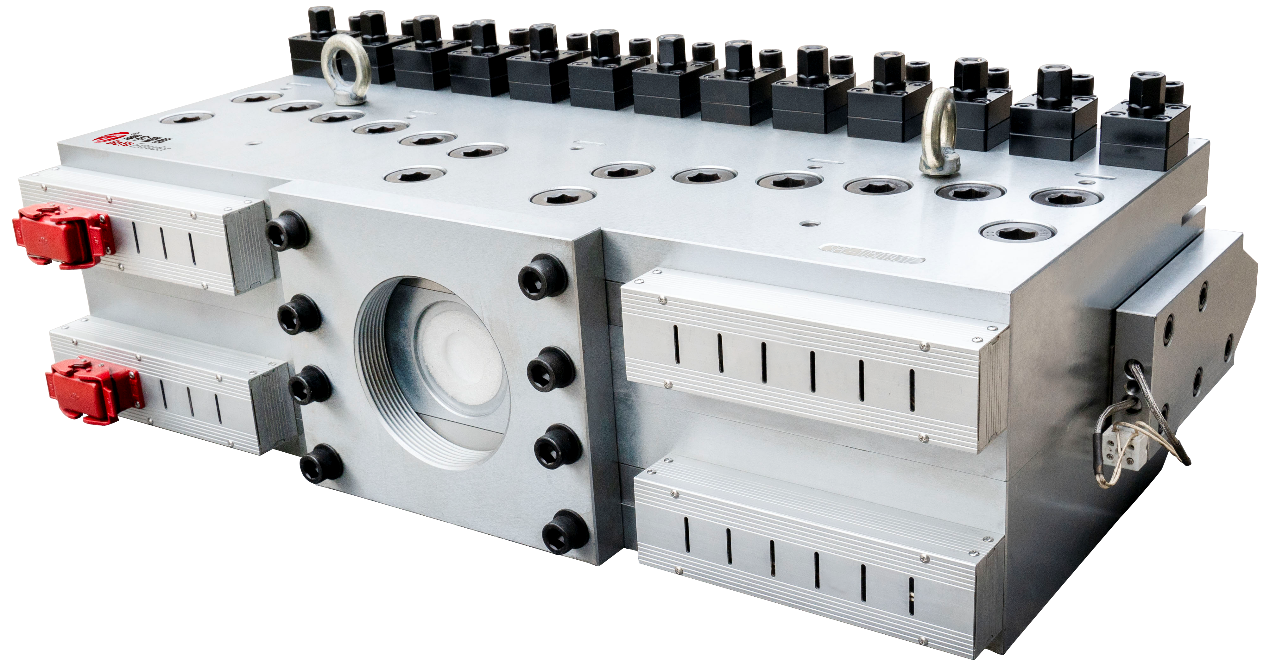

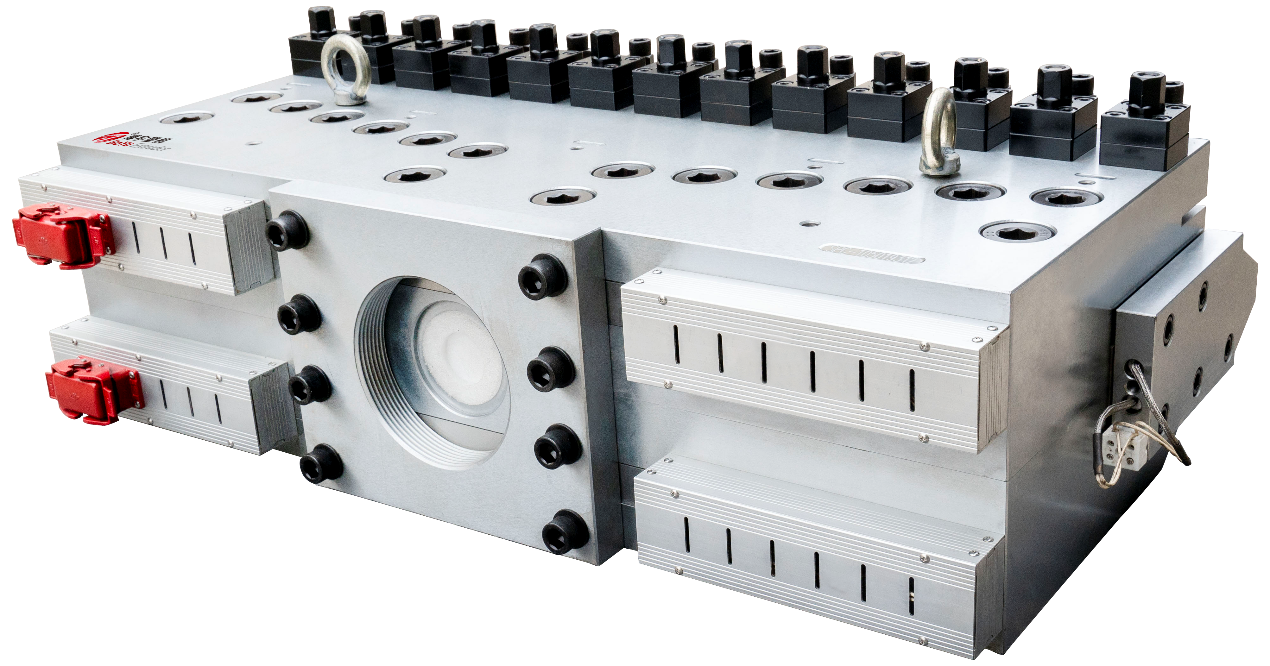

Extrusion, a transformative manufacturing process, empowers industries to create objects with consistent cross-sectional profiles by pushing materials through specialized tools called dies. Boyu Extruder, a pioneer in the field, prides on delivering cutting-edge plastic extrusion dies. Today, we'll explore the remarkable features and advantages of Boyu Extruder's innovative die designs, with a specific focus on blown film extrusion and pipe/tubing forming applications.

Blown Film Extrusion Die Designs

Boyu Extruder spearheads progress by offering a range of blown film extrusion die designs meticulously designed to meet diverse film quality requirements and polymer melt characteristics. Let's delve into the exceptional options available:

1. Spider Die: The Spider die boasts a complex design, comprising an internal mandrel connected to the outer die wall via several "legs." While the resulting film may exhibit weld lines, it's crucial to note that these lines are weaker than the surrounding polymer and possess distinct optical characteristics. They arise due to incomplete healing of the polymer molecular matrix. Additionally, the spider legs generate a pressure gradient, leading to nonuniform die swell and resulting in thicker areas within the film. However, Boyu Extruder employs advanced techniques to optimize the healing process, ensuring superior film quality.

2. Crosshead Die: The Crosshead die exhibits a relatively simple design, dividing the melt flow into two parts at the manifold inlet before recombining them opposite a cylindrical center mandrel. Despite its simplicity, this die design may produce non-symmetrical flow. The delay experienced by molecules reaching the opposite side of the mandrel from the closer side contributes to non-uniform film thickness. Boyu Extruder overcomes this challenge by implementing varying inlet diameters to reduce nonuniformity. Additionally, the strategic inclusion of different inserts minimizes stagnant regions, leading to a more consistent and high-quality film output.

3. Spiral Die: Among the three plastic extrusion die designs, the Spiral die stands out as the most intricate. It uniformly distributes the polymer melt into several feed tubes, which gracefully wind around a central mandrel. Each feed tube connects to the space between the outer die walls and the mandrel. As the feed tubes spin around the mandrel, diameters gradually decrease, concurrently increasing the space between the mandrel and outer die walls. This intricate process facilitates the layering and blending of the polymer melt, culminating in a uniform melt profile that eliminates the presence of weld lines. Boyu Extruder's Spiral die guarantees exceptional film quality, characterized by uniform thickness and enhanced optical properties.

Pipe/Tubing Forming Die Design

Boyu Extruder's expertise extends seamlessly to pipe/tubing forming die designs. This type of extrusion die shares remarkable similarities with blown film extrusion dies. The primary distinction lies in the gap existing between the inner mandrel and the outer die wall. To facilitate an efficient cooling process, Boyu Extruder utilizes water baths or cooling fans to expedite the polymer melt's cooling. Following cooling, flexible tubes are neatly wound onto large spools, while stiff tubes are precisely cut into preset lengths and stacked. This versatile and reliable die design enables the continuous extrusion of thick-walled tubes and pipes, catering to diverse industry requirements.

Conclusion

Boyu Extruder's plastic extrusion die designs reflect an unwavering commitment to precision and versatility. By embracing our advanced technologies, manufacturers can harness a wide array of advantages, including uniform film thickness, improved optical characteristics, and efficient cooling processes. Boyu Extruder's dies mark a revolution in the plastic extrusion landscape, empowering businesses to meet and exceed customer expectations. Experience the transformative power of Boyu Extruder's plastic extrusion die designs and elevate your extrusion capabilities to new heights.