In the realm of plastic extrusion manufacturing, wet plastic extrusion stands out as a process that requires the application of an external heat source, such as steam, directly into the extrusion barrel. Boyu Extruder, a leading name in the industry, offers advanced wet extrusion equipment designed to enhance the efficiency and quality of your extruded materials. This article explores the concept of wet plastic extrusion, highlighting the benefits of Boyu Extruder's equipment, and showcasing their comprehensive range of production line solutions.

Achieving Optimal Temperature and Pressure in Wet Extrusion

In wet extrusion, achieving the desired temperature is crucial for successful extrusion. Boyu Extruder's equipment employs a combination of preconditioning and steam injection to ensure precise temperature control throughout the extrusion process. This careful regulation of temperature allows for the efficient extrusion of aquatic feed, resulting in high-quality products.

Moreover, wet extrusion also involves maintaining appropriate pressure levels. Boyu Extruder's wet extrusion equipment is designed to handle the required pressure difference between the internal extruder and the external environment. This capability ensures smooth and consistent extrusion, eliminating the risk of defects and ensuring the production of flawless end products.

Environment-Friendly and High-Quality Output

At Boyu Extruder, we prioritize both environmental sustainability and product quality. Our wet extrusion equipment is built with the latest technology and adheres to stringent environmental standards. By utilizing our equipment, you can manufacture floor materials that are not only high in quality but also free from formaldehyde and heavy materials. This commitment to eco-friendly manufacturing ensures that your end products meet the expectations of environmentally conscious consumers.

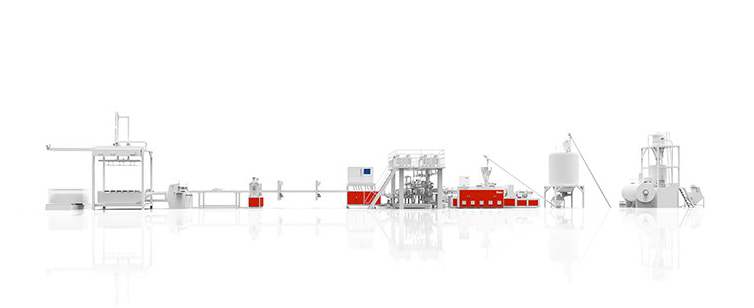

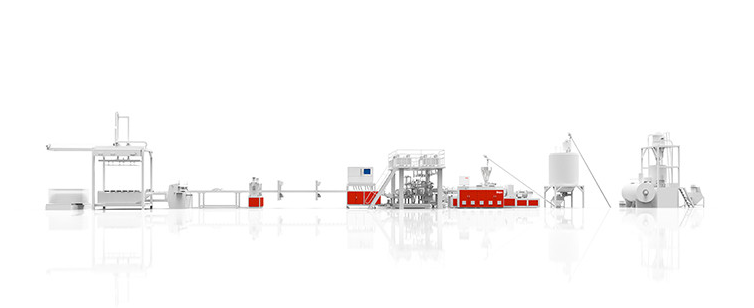

Comprehensive Solutions for All Your Production Needs

Boyu Extruder takes pride in offering a comprehensive range of production line solutions to cater to diverse industry requirements. Whether you are in the market for SPC and PVC floor production lines or WPV floor/PVC foam board lines, we have you covered. Our extensive catalog of solutions is designed to meet the specific demands of each production process, ensuring optimal performance and efficiency.

Conclusion

When it comes to wet plastic extrusion and plastic extrusion manufacturing as a whole, Boyu Extruder stands as a reliable and trusted partner. Our wet extrusion equipment is engineered to deliver exceptional results, guaranteeing precise temperature control and consistent pressure during the extrusion process. With a strong commitment to environmental sustainability and high-quality output, Boyu Extruder is the ideal choice for enhancing the efficiency and quality of your extruded materials.