Extrusion, a transformative manufacturing process, relies on the ingenuity of extrusion die design to shape materials into objects with fixed cross-sectional profiles. At Boyu Extruder, we immerse ourselves in the art of extrusion die design, unlocking possibilities that redefine the manufacturing landscape. Join us as we explore the advantages of extrusion and delve into the intricacies of one specific type ¨C "Blown Film Extrusion."

Advantages of Extrusion: Shaping the Future

Extrusion, as a manufacturing process, offers a trifecta of advantages that make it a preferred method in various industries. The ability to precisely shape materials, create complex profiles, and maintain consistency in cross-sectional profiles sets extrusion apart. At Boyu Extruder, we pride ourselves on harnessing these advantages to deliver cutting-edge solutions in extrusion die design.

Blown Film Extrusion: Unraveling the Art of Creation

One fascinating avenue in extrusion die design is the realm of "Blown Film Extrusion." This technique unfolds a world of possibilities, producing everyday items like shopping bags and continuous sheeting. The choice of plastic extrusion dies in blown film extrusion plays a crucial role, dictating the final quality and characteristics of the film produced from the polymer melt.

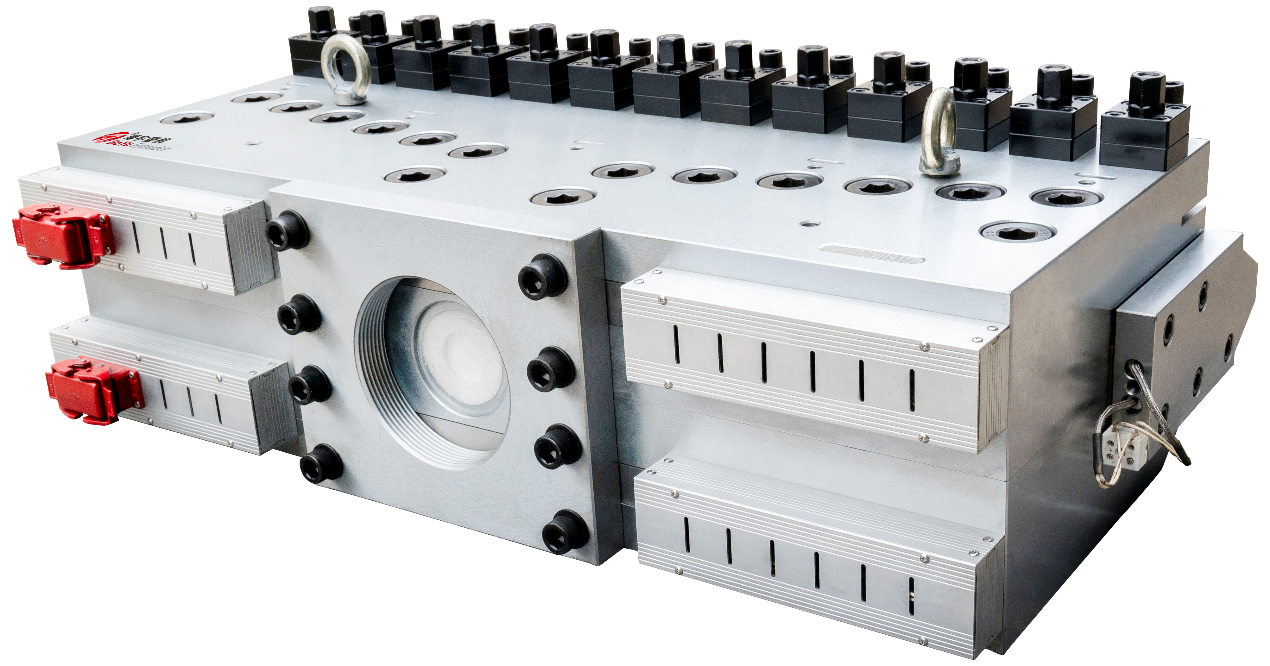

Spider Die: A Complex Design Unveiled

Among the diverse types of plastic extrusion dies used in blown film extrusion, the Spider die stands out for its complexity. This intricate design comprises an internal mandrel connected to the outer die wall by several "legs." The result is a film with weld lines, a distinctive feature of the extrusion die design. These weld lines, though weaker than the surrounding polymer, possess unique optical characteristics due to the incomplete healing of the polymer molecular matrix.

Challenges and Solutions: Navigating Die Swell

While the Spider die introduces weld lines, it also poses challenges such as nonuniform die swell. The pressure gradient generated by the spider legs contributes to the uneven thickness of the resulting film. At Boyu Extruder, we thrive on turning challenges into opportunities. Our commitment to excellence in extrusion die design extends to addressing these nuances, ensuring that the final product meets the highest standards.

Conclusion: Elevating Possibilities with Boyu Extruder

In the intricate dance of extrusion die design, Boyu Extruder emerges as the orchestrator of excellence. We understand that each design type presents its own challenges and opportunities. Our expertise lies in navigating these complexities, ensuring that your extrusion process is not just efficient but a masterpiece of innovation. When it comes to extrusion die design, choose Boyu Extruder ¨C your partner in crafting a future where possibilities are endless, and designs are unparalleled.